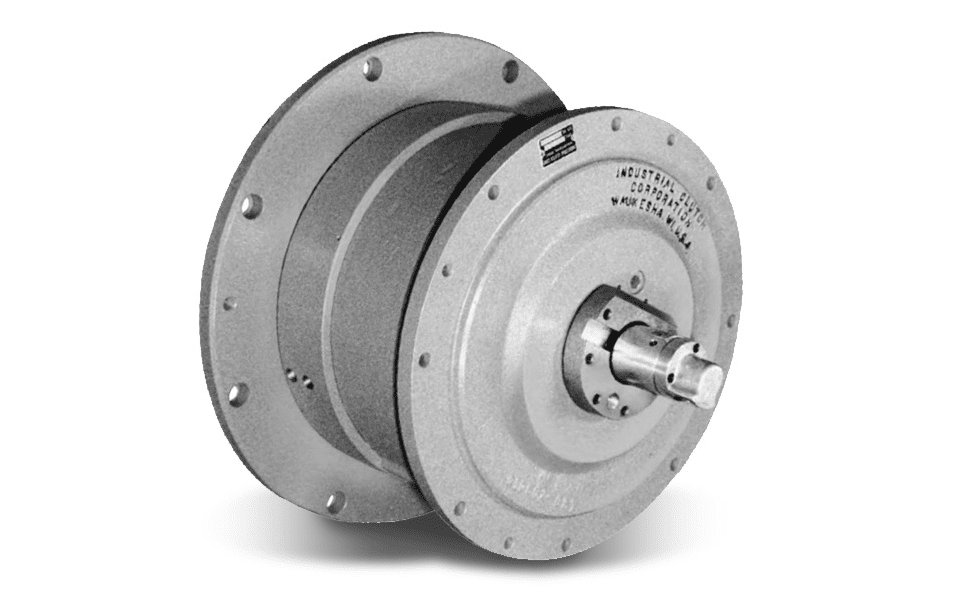

Disc clutches and brakes utilize a piston to move internal discs axially. They’re are available for either pneumatic or hydraulic actuation. Spring set configurations are used for applications where failsafe operation is required.

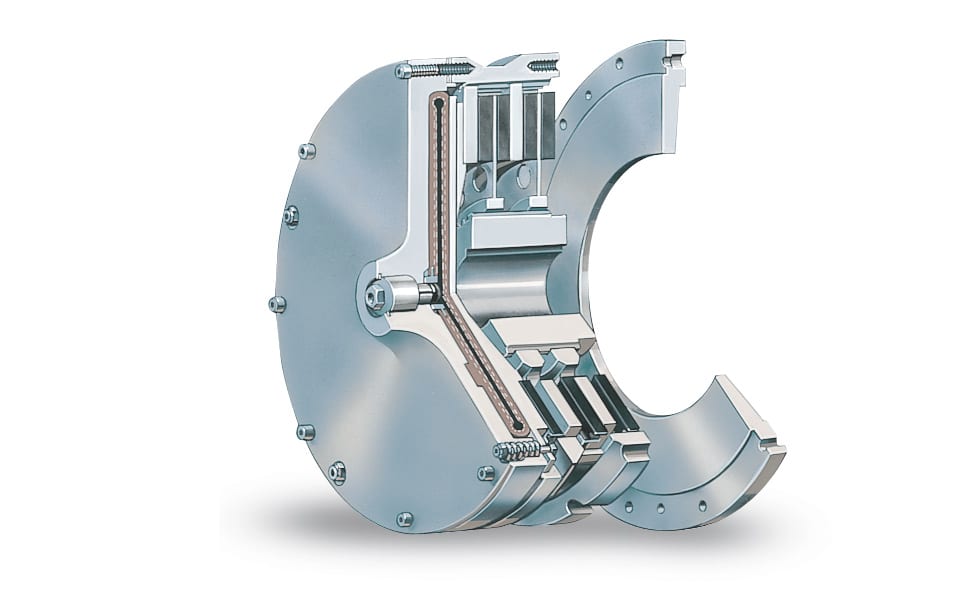

CBC CLUTCH/BRAKE COMBINATION

The Eaton CBC combines an air actuated disc clutch and a spring applied disc brake. Due to the CBC’s simple design, overlapping can’t occur between clutching and braking. This combination clutch/brake is ideally suited for high speed, high cyclic applications.

Dynamic brake torque range: 10,900 to 135,000 lb-in (1,231 to 15,253 Nm)

Static clutch torque range: 18,700 to 290,000 lb-in (2,113 to 32,765 Nm)

Typical applications: Punching machines, printing machines, shears, stamping and forming presses

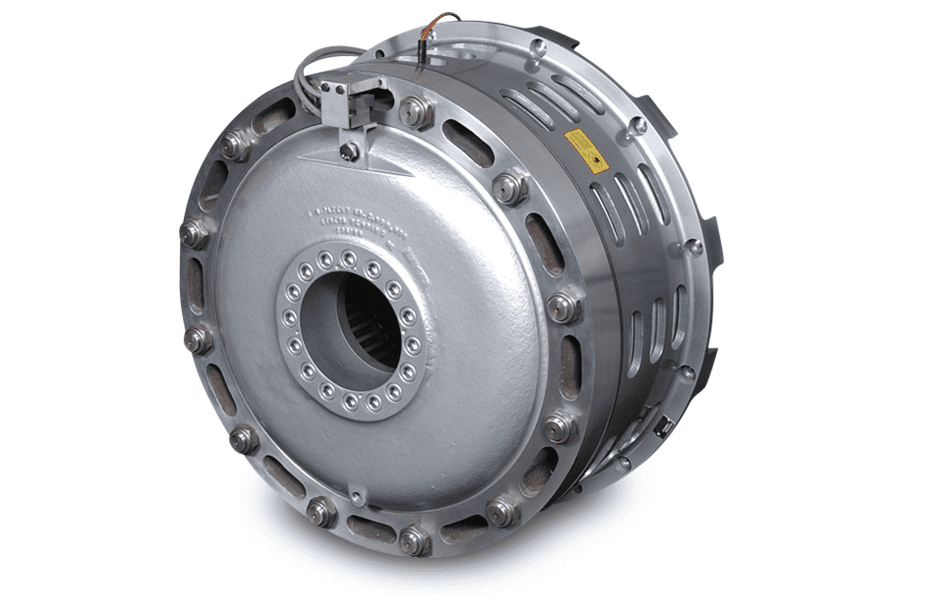

CBH CLUTCH/BRAKE COMBINATION

Industrial Clutch CBH combination clutch-bakes are oil immersed units with a spring-set brake and hydraulically-set clutch. They are designed for extremely high cyclic rates for those applications that require a high degree of stopping accuracy.

Torque range – 30,000 to 90,000 lb-in (Clutch), 10,000 to 20,000 lb-in (Brake)

Typical applications – Turret Punch Presses

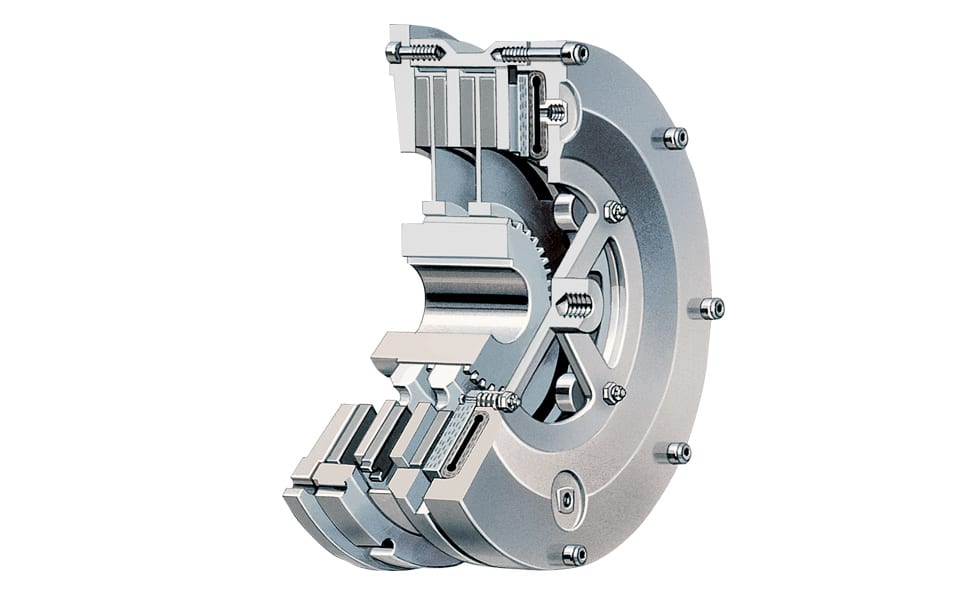

CCB – CLUTCH/BRAKE COMBINATION

Wichita Clutch/Brake Combination (CCB) units provide fast, smooth cycling for stamping presses and metal forming equipment by combining a high performance clutch and spring set brake in a compact assembly. A single air tube actuates both the single plate clutch and the single plate brake.

Torque range –23,000 to 540,600 lb-in (Clutch), 4,500 to 258,400 lb-in (Brake)

Typical applications – Stamping Presses, Can Making Equipment

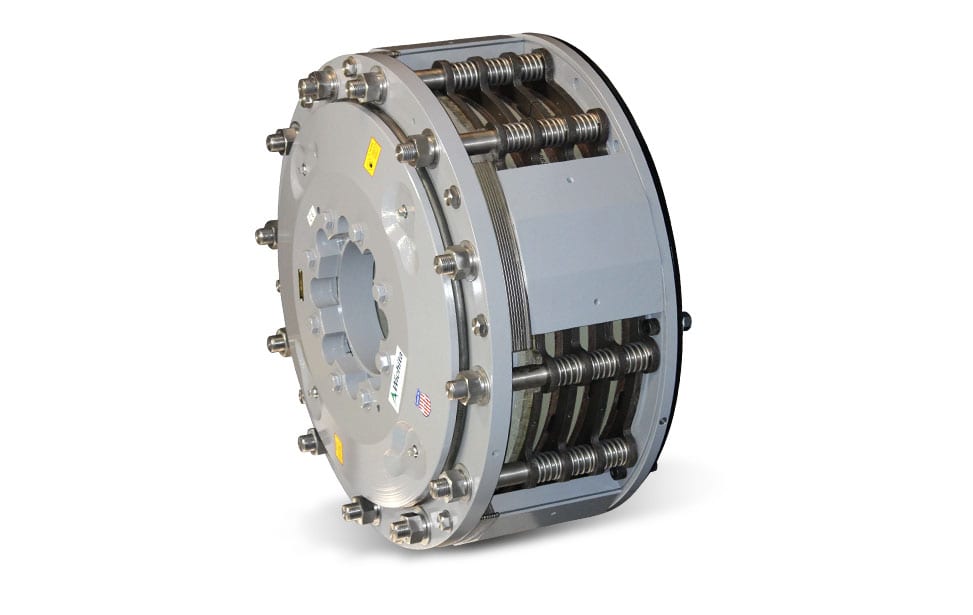

CH SERIES CLUTCHES AND BRAKES

Logan CH clutches and brakes can be air or hydraulically actuated and can be used for either wet or dry operation. Pressurizing the actuating cylinder causes the clutch’s discs to clamp. Torque is then transferred from the disc pack to the splined drive ring. Type CH clutches are approved by the American Bureau of Shipping (ABS).

Torque range: 49,000 to 1,280,000 lb-in (5,532 to 144,000 Nm)

Typical applications: Marine propulsion, mooring winches, mine hoisting equipment, mining conveyors

CU/CX DISC BRAKES

Johnson CU and CX Series DC magnetic disc brakes are dust and drip protected, and the terminal box uses an IP55 enclosure. They are used for service duty (CU) or emergency stop duty (CX).

Braking force: 809 to 50,600 lb (3.6 to 225 kN)

Typical applications: Cranes, conveyors, mining, steel mill machinery, nuclear power, oil field machinery

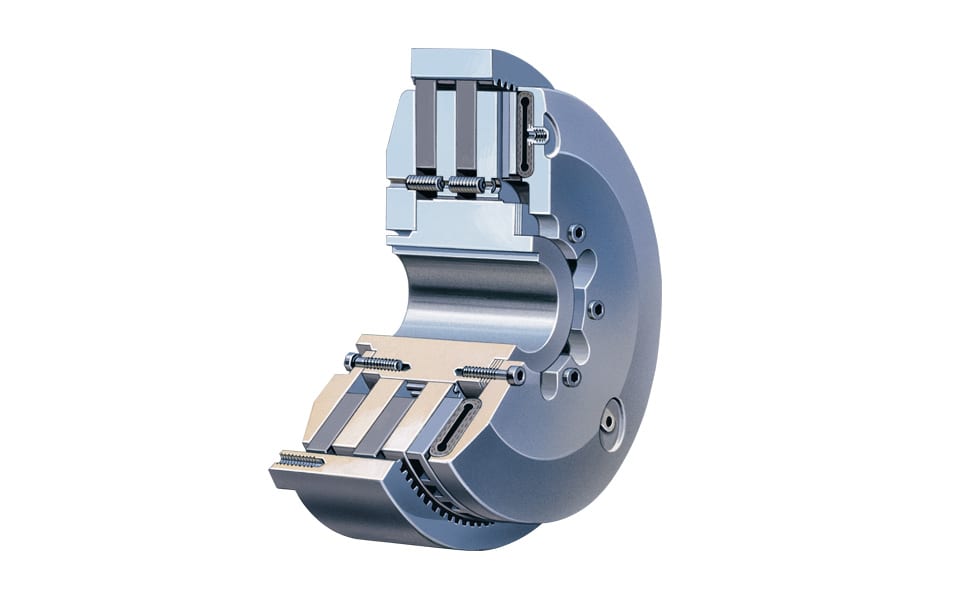

DBA BRAKES

Model DBA brakes are spring applied, pressure released, disc style brakes. They develop equal torque in either direction of rotation. Their torque and thermal capacities allow them to be used in the most demanding applications.

Brake construction and operation is shown in the figure. Pressurizing the brake compresses the brake springs and withdraws the clamping plates from the brake discs. Standard brakes are furnished with either one or two discs, which are free to move axially.

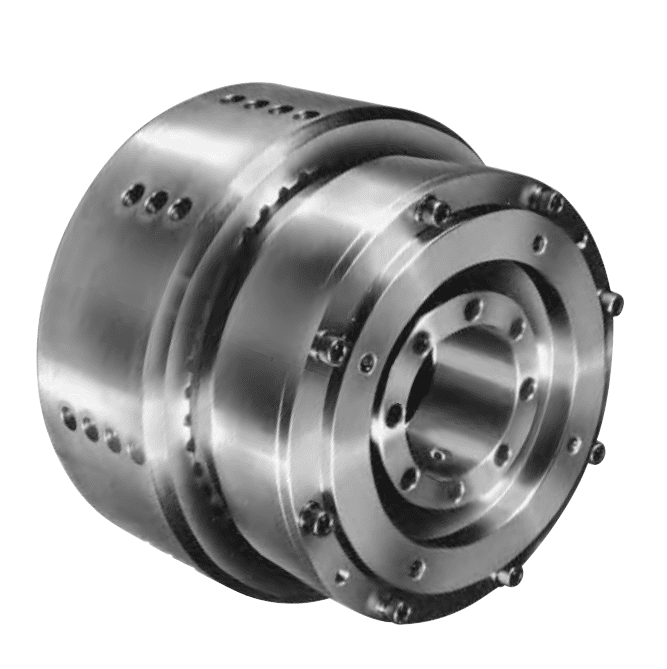

DBB BRAKES

Eaton’s DBB disc brakes are spring applied and air or hydraulically released. The rotating components’ low inertia makes the DBB ideal for cyclic applications.

Torque range: 7,500 to 1,470,000 lb-in (847 to 166,101 Nm)

Typical applications: Bottling equipment, conveyors, shears

DC CLUTCHES AND BRAKES

The Eaton Airflex type DC element is smaller than most other type clutches with comparable torque ratings. It has low inertia and is pressure actuated and spring released.

Torque range: 10,500 to 2,240,000 lb-in (1,190 to 252,900 Nm)

Typical applications: Power presses, tension brakes, unwind stands

DISC-O-TORQUE CLUTCH

The TB Wood’s Disc-O-Torque friction disc clutches can operate wet or dry, and with hydraulic or pneumatic actuation. The have high torque density, long life, and are self-contained.

Torque range: 50 to 1,776 lb-ft (67 to 2,407 Nm)

Typical applications: Machine tools, conveyors, pumps

FHB BRAKES

Eaton Airflex’s FHB brake uses a patented floating housing design in place of the usual floating rotor. This air-cooled disc brake is spring applied and pressure released. It’s particularly well suited for heavy-duty industrial applications like those found in surface mining and oilfield machinery.

Torque range: 288,000 to 432,900 lb-in (32,540 to 48,918 Nm)

Typical applications: Dragline hoist, drag, swing, and propel/walk

HC CLUTCH

Wichita HC clutches are an oil-immersed clutch designed for end-shaft or through shaft mounting configuration. The compact size of the HC makes these units ideal for incorporation within a gear housing. All torque transmitting members are designed to provide for continuous heavy duty industrial service.

Torque range – 8,511 to 191,028 lb-ft (11,540 to 259,000 Nm)

Typical applications – Marine Gears, Winch Drives and Conveyors

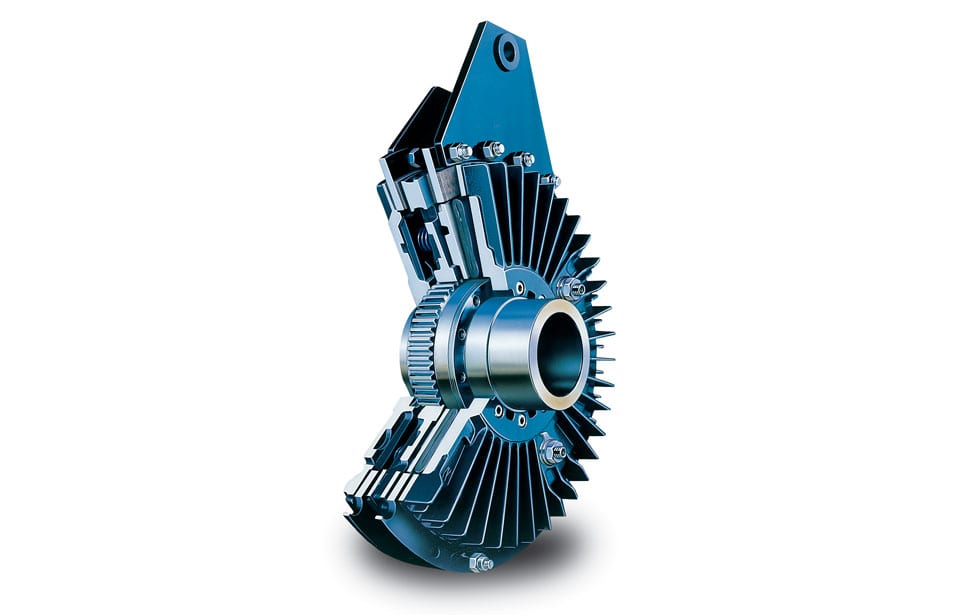

HIGH TORQUE CLUTCHES

Wichita High Torque Clutches (HTC) are designed for end-shaft mounting onto a bearing supported flywheel or gear wheel. They provide the highest torque to size ratio of any Wichita clutches.

Torque range – 800 to 7,080,000 lb-in (90 to 799,910 Nm)

Typical applications – Presses, Shears, Bulk Material Handling and General Industrial Equipment

LKB BRAKES

Industrial Clutch LKB brakes are a spring-set, air or hydraulic released brake. This design offers a wide range of torque capacities and release pressures, with total attention given to maximizing ventilation for dissipating large thermal loads. The benefits include longer lining life, stable friction coefficients and lower maintenance costs.

Torque range – 4,500 to 1,360,000 lb-in (508 to 153,659 Nm)

Typical applications – – Presses, Shears, Bulk Material Handling and General Industrial Equipment

LOW INERTIA CLUTCHES AND BRAKES

Wichita Low Inertia clutches and brakes are air applied, spring released disc style units that develop torque proportional to the air pressure applied. The units are designed to be free from effects of centrifugal force and self-energization. Low inertia start/stop parts reduce acceleration times, which allows more cycles per minute, as well as reducing heat generation.

Torque range – 3,160 to 17,850,000 lb-in (340 to 1,204,000 Nm)

Typical applications – Presses, Shears, Bulk Material Handling and General Industrial Equipment

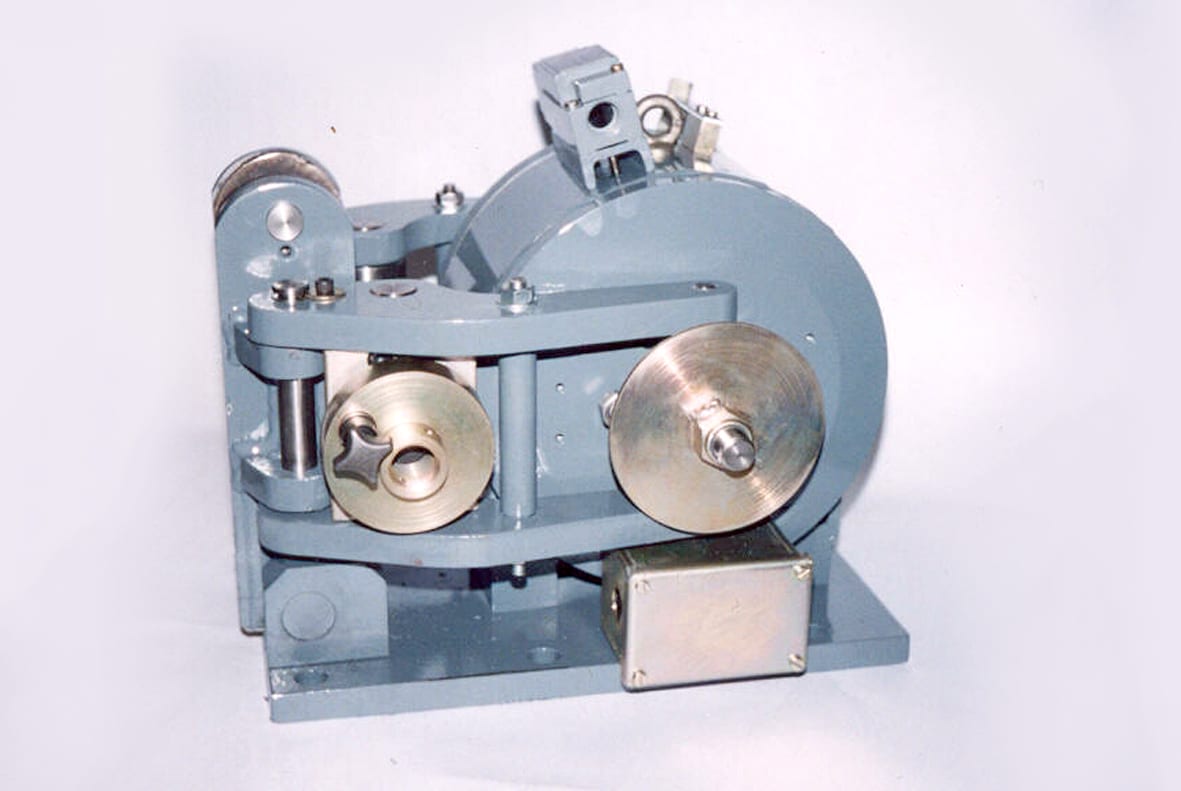

LUTEX LKB CLUTCH/BRAKE

The Desch Lutex LKB combination clutch/brake (C-B-C) has a low moment of inertia and a compact design. The brake is spring applied, and when sufficient air pressure is applied, the brake disengages, engaging the clutch. The LKB series covers most standard clutch/brake mounting arrangements.

Clutch torque: 184 to 84,820 lb-ft (250 to 115,000 Nm)

Brake torque: 103 to 47,941 lb-ft (140 to 65,000 Nm)

Typical applications: Presses, shears

MESLU CLUTCHES

American Vulkan Meslu clutches are dry-running, pneumatically actuated double-cone clutches. They operate backlash-free and produce no axial load. Friction lining wear is automatically compensated for.

Torque range: 5,900 to 232,332 lb-ft (8 to 315 kNm)

Typical applications: Dredge pumps, marine drives, auxiliary drives

PDC CLUTCH

The Eaton Airflex Pneumatic Disc Clutch has a simple design, utilizing an air tube to actuate the clutch’s plates. It features low friction wear, reduced heat generation, and easy maintenance.

Torque range: 65,000 to 843,000 lb-in (7,345 to 95,254 Nm)

Typical applications: Drawworks, dredging, recycling/shredding, logging equipment

PLANOX PP CLUTCH

Desch Planox PP clutches are pneumatically actuated. The design is simple, maintenance-free, and sturdy. PP clutches have a successful track record in applications with high engaging/disengaging frequency.

Torque range: 95 to 59,521 lb-ft (130 to 80,700 Nm)

Typical applications: Construction machinery, marine drives, energy generation, extruders

SERVOX BRAKE

The Desch Servox brake is spring applied, hydraulically released. It’s usually used as a static holding brake, but can function as a dynamic safety brake.

Torque range: 8,113 to 22,126 lb-ft (11,000 to 30,000 Nm)

Typical applications: Presses

STANDARD VENT CLUTCH

Wichita Clutch Standard Vent clutches are designed for reliable in-line power transmission. The simple air-tube design, with small air volume, speeds engagement and disengagement. It is ideally suited for large inertia loads where smooth controlled starts are needed.

Torque range – 7,000 to 30,955,750 lb-in (790 to 3,497,530 Nm)

Typical applications – Drilling rigs, Grinding Mills

Spring Set Brakes

Wichita Clutch Spring Set Brakes (SSB) are ideal for safe protection of process equipment. The units are similar to the Low Inertia units and designed to be free from effects of centrifugal force and self-energization. Low inertia start/stop parts reduce acceleration times which allows more cycles per minute as well as reducing heat generated.

Torque range – 451 to 5,355,000 lb-in (51 to 605,016 Nm)

Typical applications – Presses, Shears, Bulk Material Handling and General Industrial Equipment