Clutch Engineering is an authorized distributor for Industrial Clutch, offering advanced product solutions from their lineup of specialized parts. We specialize in the identification and distribution of industrial power transmission products that are ideal options for various mechanical systems. We are proud to feature products such as clutches, brakes, and combination clutch/brakes from Industrial Clutch, because we know that these great products can be matched with the needs of many applications. Clutch Engineering’s knowledgeable customer service and technical support staff will help you select the right product, so you can be certain that you are ordering the right parts for your system. The high-standards of production that are met and exceeded for every product can be experienced through the quality and reliability of each integrated part.

Founded in 1930, Industrial Clutch has been recognized as a front-running manufacturer of clutches, brakes, and controls for a variety of heavy-duty applications. Industrial Clutch specializes in providing standard, modified or custom-engineered solutions to OEM’s and designers to meet their specific power transmission needs. Clutches and brakes from Industrial Clutch are able to be implemented into a large variety of applications, due to a diverse product selection that can address different specialized needs. Dry clutches and brakes are also available, and there are options for oil immersed clutches and brakes to consider as well. These clutch and brake products are designed to fit well into many mechanical systems.

Industrial Clutch has a complete product line of low-inertia, dry clutches and brakes (Type LKB) as well as wet, oil-immersed models (Type HC) which use oil shear technology. This technology is required for many rugged applications. Industrial Clutch supports a variety of application in industries that include metal forming, mining, oil & gas, forestry and marine applications. If you are designing a new machine or maintaining an existing one, Clutch Engineering is your best source for genuine Industrial Clutch parts and expert technical support. Contact our team for additional information about these and other high-quality clutch and brake products.

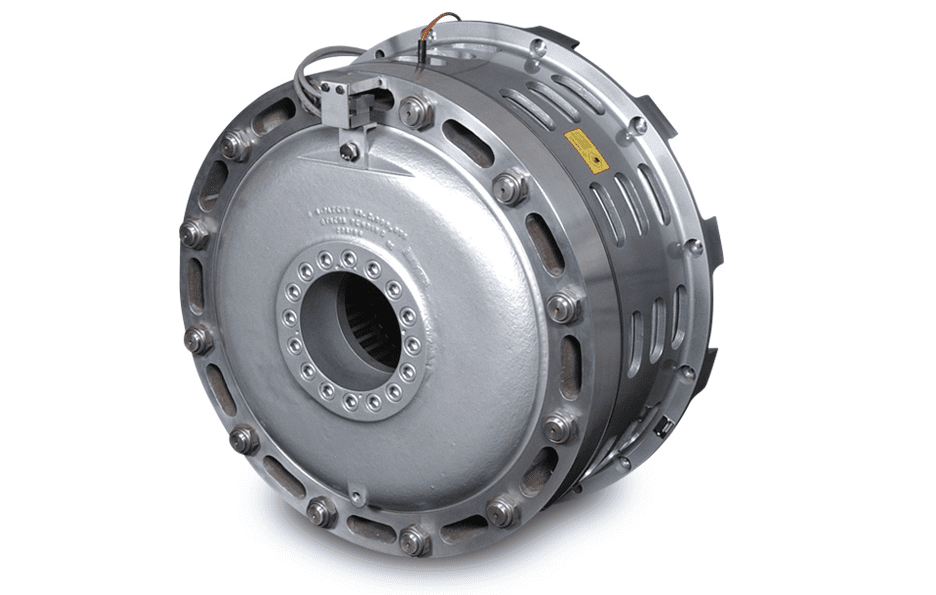

LKB Brakes

These Industrial Clutch LKB brakes feature high-quality non-asbestos lining materials. In these products offered by Clutch Engineering, maximum areas ensure excellent heat dissipation, uniform stopping distances, and long lining life. Industrial Clutch LKB brakes are spring-set, and air or hydraulically released. This design offers a wide range of torque capacities and release pressures, with total attention given to maximizing ventilation for dissipating large thermal loads. Longest possible spline length is incorporated on the brake discs to maximize the load-carrying capacity. Additional benefits include stable friction coefficients and lower maintenance costs.

Torque range – 4,500 to 1,360,000 lb-in (508 to 153,659 Nm)

Typical applications – – Presses, Shears, Bulk Material Handling and General Industrial Equipment

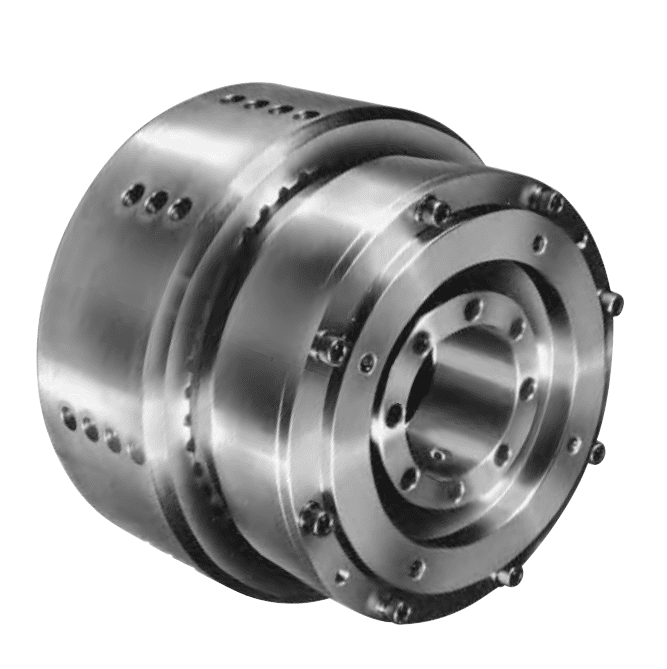

HC Clutch

The compact size of the HC Clutch makes these units perfect for incorporation within a gear housing. Clutch Engineering offers these Wichita HC clutches, which are oil-immersed clutches designed for end-shaft or through shaft mounting configuration. All torque transmitting members are designed to perform for continuous heavy duty industrial operation. All units incorporate provisions for forced oil cooling allowing high energy engagements to be made without causing thermal distress within the disc pack. Cooling oil is introduced into the clutch from an external supply. This oil enters the unit through axial holes located in the shaft.

Torque range – 8,511 to 191,028 lb-ft (11,540 to 259,000 Nm)

Typical applications – Marine Gears, Winch Drives and Conveyors

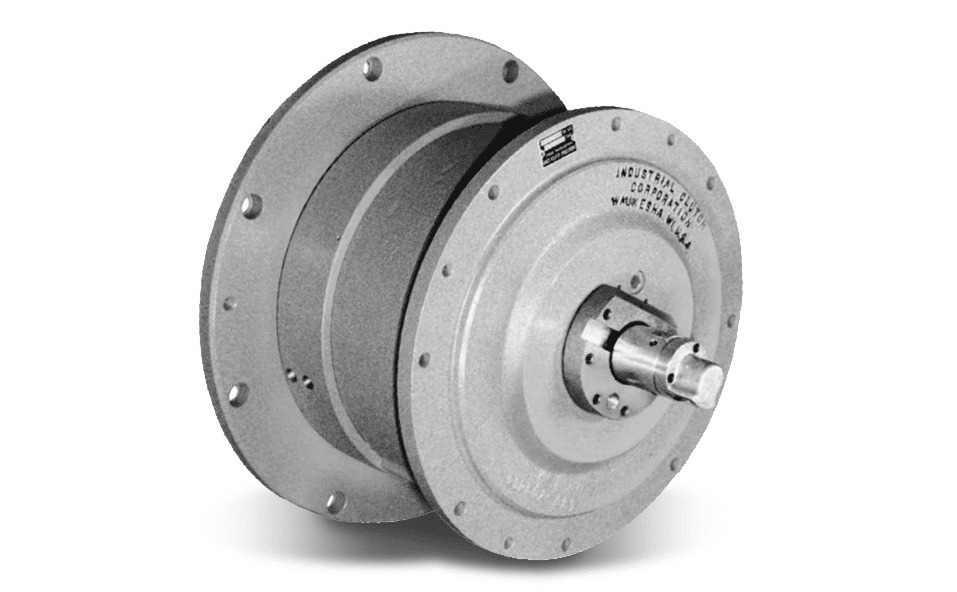

CBH Clutch/Brake Combination

These CBH Clutch/Brake Combination products are made for extremely high cyclic rates. Clutch Engineering offers these for use in applications that require high degrees of stopping accuracy. Industrial Clutch CBH combination clutch-bakes are oil immersed units with a spring-set brake and hydraulically-set clutch. Hydraulic actuation and precise control of piston stroke contributes to an extremely fast response time. Actuation volumes are very small and the fluid’s virtually incompressible characteristics means that piston motion times can be as low as 5-10 milliseconds.

Torque range – 30,000 to 90,000 lb-in (Clutch), 10,000 to 20,000 lb-in (Brake)

Typical applications – Turret Punch Presses