Our Closed-Loop Systems will maintain peak performance from your water-cooled machinery and cut installation and operating costs.

Costs and Operational Advantages

CEC's industrial coolers are specifically designed to dissipate the heat generated in a variety of industrial machinery. Compare our closed-loop solution to your current method for cooling your machinery:

- CEC coolers recirculate one tank of water, eliminating the need for a continuous and expensive on-line water supply.

- CEC coolers also eliminate the complications and expense of industrial effluent. Your water will no longer pass through once and be a disposal problem.

- CEC coolers cut installation costs. Because they are self-contained, they can be positioned next to the equipment they are cooling. There is no need to install long runs of pipe from a remote water source.

- CEC coolers perform well in cold weather. If your location experiences periodic cold temperatures, anti-freeze will prevent any freeze-ups.

- CEC coolers eliminate the mineral deposit buildup in your equipment that often is associated with an on-line fresh water source.

- CEC coolers eliminate condensation on your equipment because water temperatures are higher than ambient.

- CEC coolers will give a long service life. They are constructed from heavy duty, corrosion resistant material for long, trouble-free operation in the toughest industrial conditions.

- CEC coolers modular design is easy to maintain.

- CEC coolers arrive fully assembled on a welded steel base that permits handling with a lift truck.

- CEC coolers come in stock capacities to handle a wide range of cooling requirements. Special designs can be accommodated.

Available from Stock

Factory Proven, Easily Installed for Any Application.

CEC Closed-Loop Coolers plumb directly to your equipment's inlet and outlet water ports with no additional plumbing required

Your Application

Water-Cooled Brakes and Clutches

Air Compressors

Hydraulic Power Units

Welding Equipment

Furnaces, Etc.

CEC

Closed-Loop

Cooler

Determining the Right Cooler for Your Application

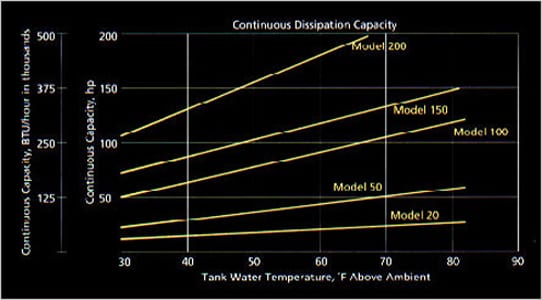

CEC water coolers come in five standard sizes with dissipation capacities of 20, 50, 100, 150, 200 and 250 hp. The procedure for selecting the right cooler for your application is:

- First, calculate the average heat load requirements of all components for which the water cooler will provide cooling water (see the graph and formulas.)

- Next, estimate the maximum temperature of the area where the cooler will be located (ambient temperature.)

- Then, from the graph below, select the cooler which can dissipate the heat load without the water tank temperature exceeding 150oF.

Calculating Heat Load

Water heat load, btu/hr = (ToFout - ToFin) x gpm x 500

Oil heat load, btu/hr = (ToFout - ToFin) x gpm x 210

Brake heat, hp =(web tension,lbs x web speed, fpm) ÷ 33,000

Clutch or brake hp = (torque, in-lb x slip rpm) ÷ 63,00

Energy equivalents:

1 hp = 42.5 btu/min = 2550 btu/hr

1 kw = 3413 btu/hr

CEC Standard Cooler Specifications

| Water Cooler Size | Model 20 | Model 50 | Model 100 | Model 150 | Model 200 | |

|---|---|---|---|---|---|---|

| Physical Dimensions | Length, Inches Width, Inches Height, Inches Tank Capacity, Gallons Ship Weight, Lbs Operational Weight, Lbs |

50 27 29 30 200 500 |

48 42 42 55 400 900 |

62 38 48 100 700 1500 |

62 38 48 100 800 1800 |

62 38 48 150 1100 2400 |

| Radiator Characteristics | Motor hp, 3-hase, TEFC Air Flow, CFM Sound Level, db |

1/4 2240 72 @ 7 ft |

1/2 5450 78 @ 7 ft |

2 5000 76 @ 25 ft |

2 7400 78 @ 25 ft |

3 10,300 83 @ 25 ft |

| Pump Characteristics | Motor hp, 3-Phase, TEFC Flow, gpm, @ 60 head in feet* @ 70 head in feet @ 80 head in feet @ 90 head in feet |

1 50 35 10 – |

1 50 35 10 – |

1-1/2 65 58 50 32 |

1-1/2 65 58 50 32 |

1-1/2 65 58 50 32 |

| Recommeded Pipe Size, Inches |

Up to 30 feet total length 30 to 80 feet total length |

1/2 3/4 |

1/2 3/4 |

3/4 1 |

3/4 1 |

3/4 1 |

Optional Features

- High water temperature cut-off switch

- Low water flow cut-off switch

- Sight flow indicator

- Low level switch