Clutch Engineering is an authorized dealer for Wichita Clutch products. We are also a rebuild center that specializes in the distribution of advanced industrial power transmission products that are needed for many mechanical systems across various industries. We are proud to offer disc, water-cooled, and air-cooled clutches and brakes from Wichita Clutch. We keep an inventory of genuine parts available, to be able to quickly respond to customer requirements and rush orders. In addition, our Application Engineers provide technical support for our customers, to ensure that you are purchasing the best parts for each planned installation. Wichita Clutch was formed in 1949 and they are now a leading global designer and manufacturer of heavy-duty clutches and brakes that are essential components in industrial process equipment.

Backed by years of extensive mechanical experience, Wichita Clutch utilizes the latest design technologies and materials to provide innovative clutch and brake solutions that precisely meet the most demanding requirements of each customer. Wichita Clutch has heavy-duty clutches and brakes that are designed to withstand the challenges of many industrial applications that exist across the globe. Mechanical solutions are available that you can integrate directly into your existing machinery, or you can enhance new equipment being introduced into your processes. These products are designed and manufactured to offer reliable, optimized performance in a multitude of settings.

Available brake solutions include brakes that are actuated by multiple methods, including brakes that are spring-applied and can finction as fail-safe systems. A full range of Wichita solutions, including air and hydraulic clutches and brakes (Low Inertia, Standard Vent, Power Take-Offs), water-cooled clutches and brakes (AquaMakks, Kopper Kool), and fluid couplings (Mesur-Fil), are seen in applications across the world. These products are used extensively in metalworking, steel, marine, pulp & paper, material handling, mining, and energy applications. Clutch Engineering can provide dependable, long-lasting units for the most demanding of industrial systems.

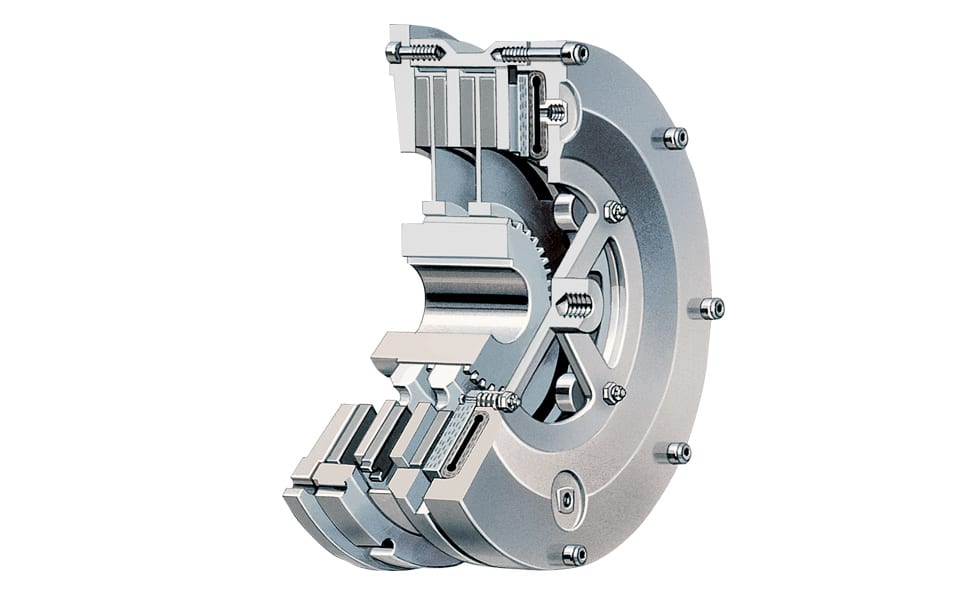

Low Inertia Clutches and Brakes

Clutch Engineering offers Wichita Low Inertia clutches and brakes, for applications that include presses, shears, and other industrial equipment. These clutch and brake parts are air applied, spring released disc style units that give you more control over your braking pressure. When in use, these products develop torque proportional to the air pressure applied. The units are also designed to be free from effects of centrifugal force and self-energization. Low inertia start/stop parts reduce the acceleration times of each unit, which allows you to benefit from more cycles per minute, as well as a reduction in heat generation. Wichita Clutches engage smoothly and quietly, without shock or impact. They are also able to utilize their spring release construction to release completely in a fraction of a second. Extremely fast action is also possible because of the small volume of air required for these high-quality clutches and brakes.

Torque range – 3,160 to 17,850,000 lb-in (340 to 1,204,000 Nm)

Typical applications – Presses, Shears, Bulk Material Handling and General Industrial Equipment

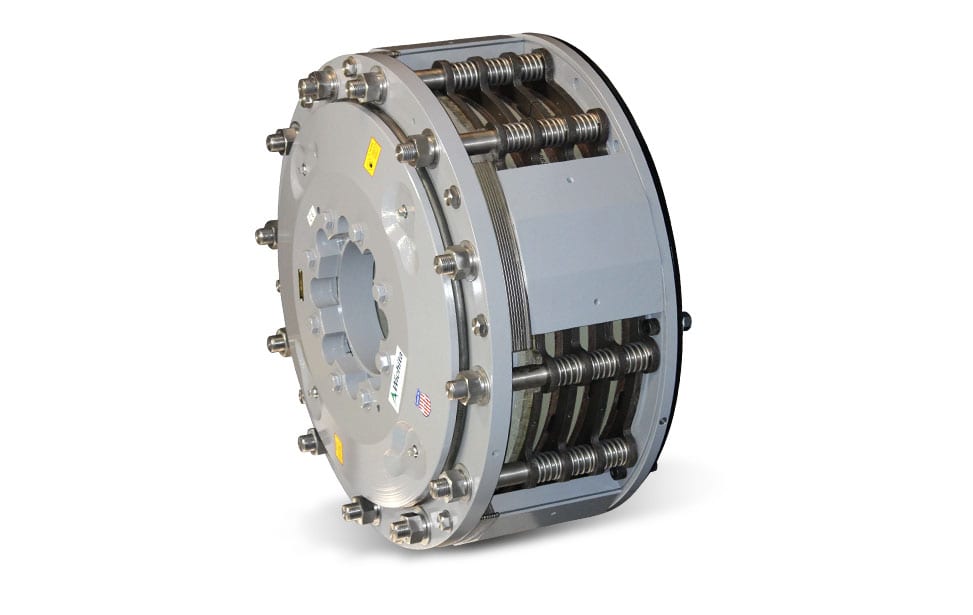

Kopper Kool Clutches and Brakes

Clutch Engineering offers Wichita Kopper Kool clutches and brakes, for applications such as drilling rigs, deck equipment, coilers, and more. These products are water cooled to achieve high thermal capacities while working within your applications. A featured hub spline provides perfect alignment of rotating discs. The units contain copper discs for excellent heat dissipation, which is a critical factor when working under conditions that will generate large amounts of heat. Engagement is achieved by pneumatic expansion of the airtube, which is an effective and reliable engagement method. This air-operated clutch also provides an accurately controlled continuous slip action for constant web tensioning.

Torque range – 2,720 to 1,600,000 lb-in (307 to 180,771 Nm)

Typical applications – Drilling rigs, Deck Equipment, Coilers, Slitters and Lumber Processing Equipment

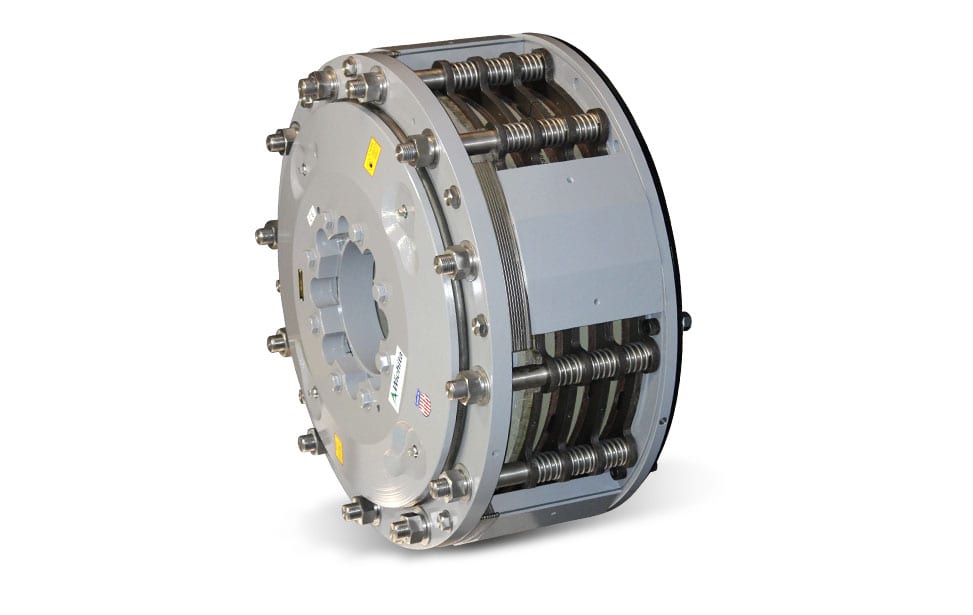

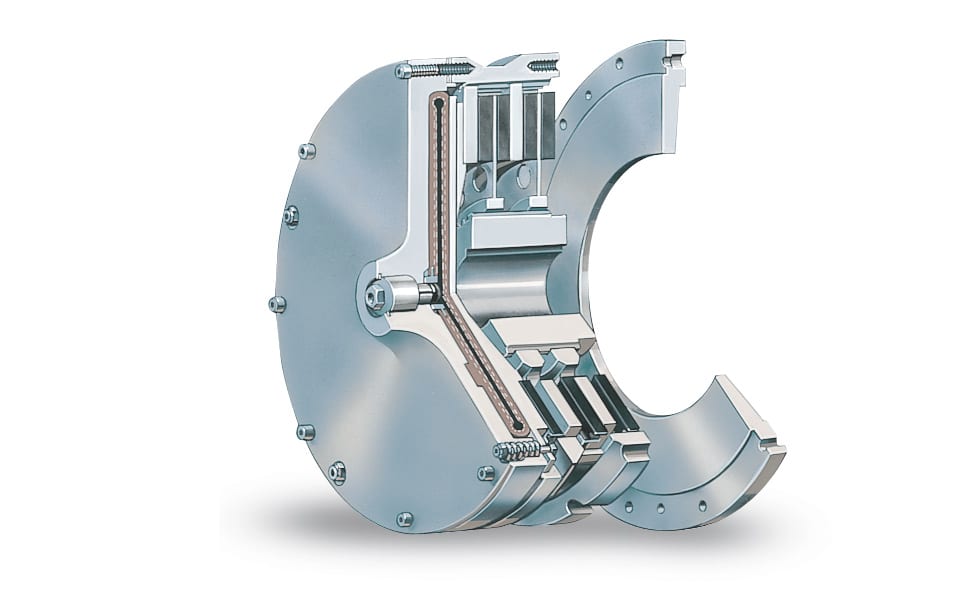

AquaMaKKs Clutches and Brakes

Clutch Engineering offers Wichita AquaMaKKs clutches and brakes. In these specialized parts, copper alloy wear plates provide great heat dissipation and consistent tension. Each unit is water cooled to allow for high thermal capacities in many challenging use cases. AquaMakks units each feature composite water jackets to reduce weight, while also improving water flow and adding resistance to corrosion. In these units, torque is transmitted by applying axial force from the pneumatic, hydraulic, or spring set actuator. Wichita engineers have utilized the latest cutting edge technologies and state-of-the-art materials to develop these composite water jackets. They are a revolutionary new breakthrough in water cooled clutch and brake design… (patent pending).

Torque range – 55,440 to 1,596,000 lb-in (6,259 to 180,188 Nm)

Typical applications – Drilling rigs, Deck Equipment, Coilers, Slitters and Lumber Processing Equipment

Standard Vent Clutch

Available from Clutch Engineering, these Wichita Clutch Standard Vent clutches are perfect for large inertia loads where smooth controlled starts are needed. The simple air-tube design of these clutches features a small air volume construction. It also accelerates engagement and disengagement. These well-made products are designed for reliable in-line power transmission, across a variety of industrial use cases. The Wichita air-tube disc design combines all the best features of a disc type clutch with all the advantages of direct air engagement. It is the simplest and most trouble-free method of applying air pressure yet designed.

Torque range – 7,000 to 30,955,750 lb-in (790 to 3,497,530 Nm)

Typical applications – Drilling rigs, Grinding Mills

Spring Set Brakes

Clutch Engineering offers Wichita Clutch Spring Set Brakes (SSB) that are used for enhanced safety in industrial environments and for the protection of various mechanical systems. Wichita Spring-Set Air Release Brakes are ideal for fail-safe protection of process equipment. These spring set brakes are similar to the available Low Inertia units, and they are also specially designed to avoid the effects of centrifugal force and self-energization that other products can face. Using low inertia start/stop parts reduces acceleration times, which leads to more cycles per minute and also reduces generated heat. Constructed of high strength cast iron, this improved design has thick friction discs for longer wear life. The fast acting airtube design also assures quick, smooth stops.

Torque range – 451 to 5,355,000 lb-in (51 to 605,016 Nm)

Typical applications – Presses, Shears, Bulk Material Handling and General Industrial Equipment

ModEvo Tension Brake

Clutch Engineering provides Wichita ModEvo tension brakes for use with light duty and medium duty tensioning applications. These high-quality products are modular, and they can operate at high line speeds while still giving smooth control. Their advanced design is optimized to achieve high heat dissipation at low speeds, with the use of cooling air. This method for heat dissipation is possible in either rotational direction. A cooling fan can also be integrated into your system for enhanced heat dissipation capabilities. Included discs are manufactured to be the same thickness and each uses the same brake modules and actuators. Each disc can be specified with a minimum of one module, up to the maximum number of modules that can be fit around the disc.

Available in five sizes: 250 mm, 300 mm, 350 mm, 400 mm and 450 mm diameters

Torque range – 12 to 38,000 lb-in (1 to 4,293 Nm)

Typical applications – Light and medium duty Tensioning Applications

Mesur-Fil Fluid Couplings

Clutch Engineering offers Wichita Mesur-Fil fluid couplings that deliver reliable and smooth power transmission in applications with high inertia loads. This product is designed with no mechanical contact of internal parts and is especially useful in soft start or overload applications. The construction of these couplings will insure minimal maintenance and long life. Wichita Clutch provides heavy-duty clutches and brakes that are designed to withstand the rigors of a wide range of industrial applications around the world.

Motor HP – ½ to 1,500 HP

Applications – Conveyors, Crushers, Shredders, Amusement Park Rides and Ski Chair Lifts

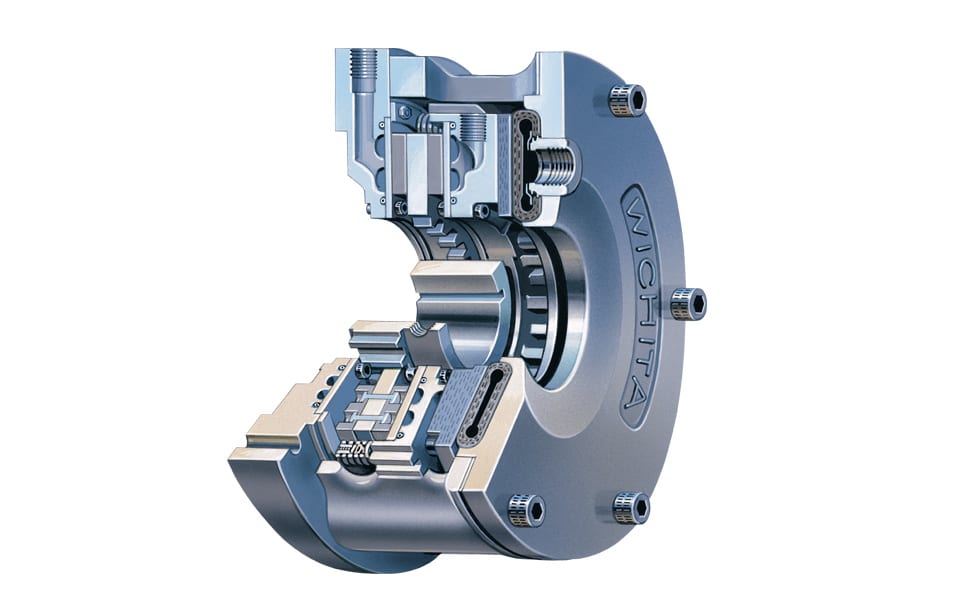

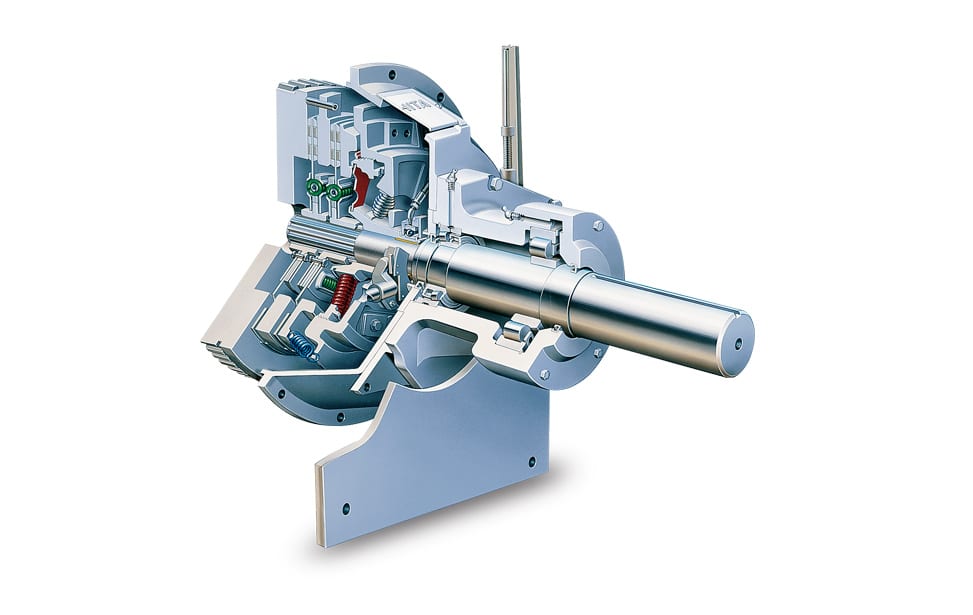

CCB – Clutch/Brake Combination

Clutch Engineering offers Wichita Clutch/Brake Combination (CCB) units, for use with applications such as stamping presses, can making equipment, metal forming equipment, and other industrial machinery. These high-quality CCB units are compact assemblies that combine a high-performance clutch and spring set brake to provide fast and smooth cycling for various industrial needs. An air tube is used to actuate both the single plate clutch and the single plate brake. The Wichita Combination Clutch-Brake can reliably function for the cycling needs of your equipment in a range of applications. The simple Wichita air tube concept combines an air actuated clutch and a spring-set brake in a compact disc design.

Torque range –23,000 to 540,600 lb-in (Clutch), 4,500 to 258,400 lb-in (Brake)

Typical applications – Stamping Presses, Can Making Equipment

PTO Clutches

Clutch Engineering offers the Wichita Power Take-Off (PTO) clutch as a high-quality PTO clutch solution for many mechanical systems. Compatible applications for PTO clutches include barge pumps, crushers, chippers, diesel engine systems, and others. The in-line PTO design of these clutches can provide direct drive operation with side load capability. These high-quality products are also available with air or mechanical clutch engagement, to better align with your system needs. Mechanical PTOs are available with an automatically adjusting clutch, require no pilot bearing, and are ideal for vehicular flywheels. Designs are available for in-line or side load applications. It has an automatic self adjusting feature and does not require a pilot bearing.

Torque range – 10,800 to 129,000 lb-in (1,220 to 14,575 Nm)

Typical applications – Barge Pumps, Crushers, Chippers, Various Diesel Engine Applications

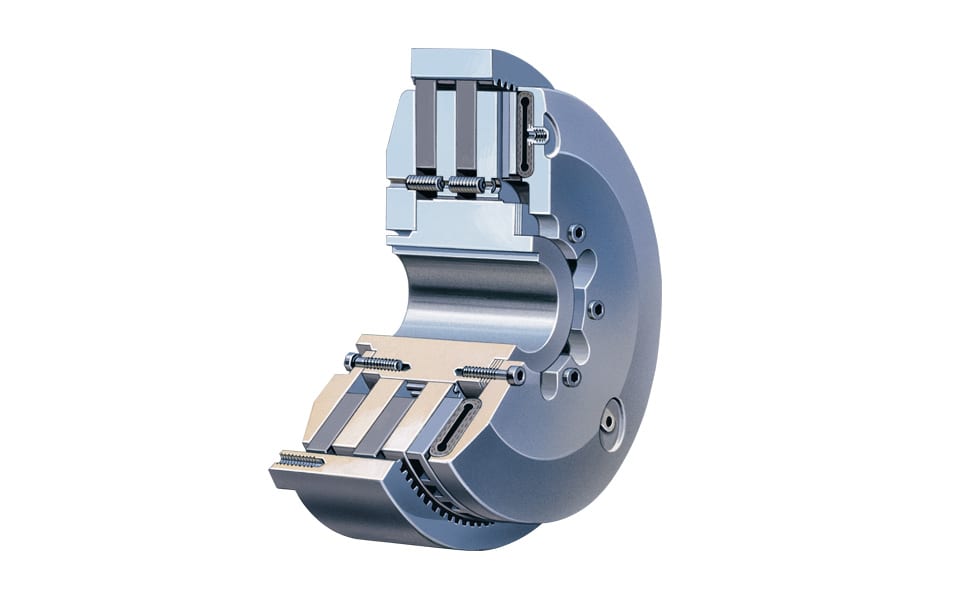

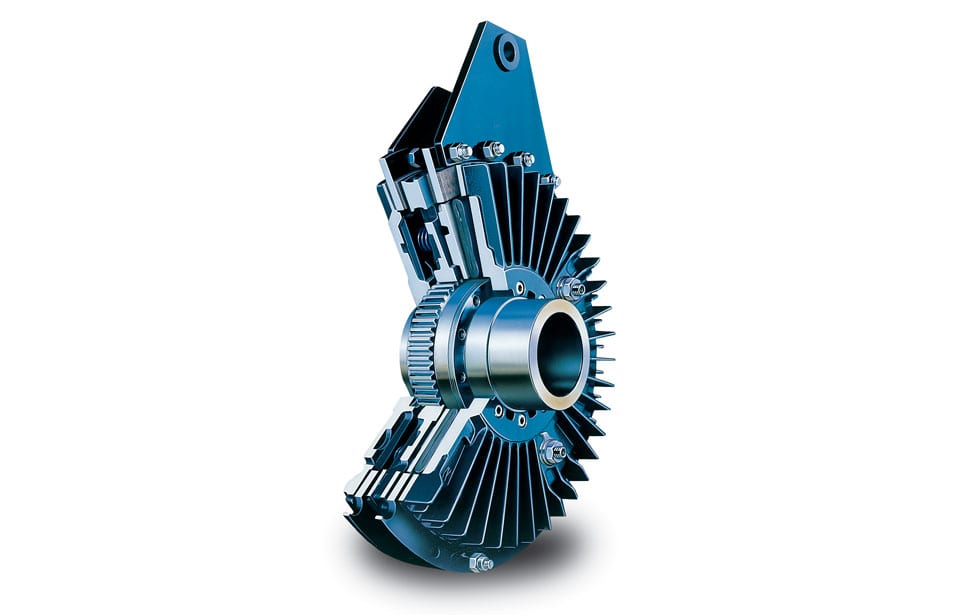

High Torque Clutches

Clutch Engineering offers Wichita High Torque Clutches (HTC) for various end-shaft mounting needs. Impressively, Wichita High Torque Clutches provide the highest torque to size ratio of all Wichita clutches. This can be invaluable for use in mechanical systems that have demanding performance standards and limited space for the integration of component parts. These products are specially designed for end-shaft mounting onto a bearing supported flywheel or gear wheel. They provide smooth controlled starts and stops and are designed to achieve minimum power loss due to low rotating inertia.

Torque range – 800 to 7,080,000 lb-in (90 to 799,910 Nm)

Typical applications – Presses, Shears, Bulk Material Handling and General Industrial Equipment