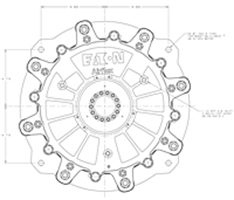

Eaton Airflex’s FHB brake uses a patented floating housing design in place of the usual floating rotor. This air-cooled disc brake is spring applied and pressure released. It’s particularly well suited for heavy-duty industrial applications like those found in surface mining and oilfield machinery.

Torque range: 288,000 to 432,900 lb-in (32,540 to 48,918 Nm)

Typical applications: Dragline hoist, drag, swing, and propel/walk

138FHB

Typical Applications

Draglines

- Hoist

- Drag

- Swing

- Propel (Walk)

Electric Shovels

- Hoist

- Crowd

- Swing

- Propel