Clutch Engineering offers a product line of reliable tension brakes and clutches. These tension brakes clutches are used in constant tension applications for various kinds of machinery. They are also suited for a variety of temperature conditions. These products are able to quickly dissipate heat through air or water cooling. This valuable ability to operate in high temperature scenarios offers you more choices within your mechanical systems. Contact our team directly for additional information.

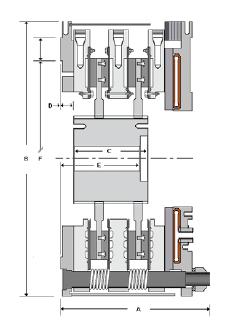

AquamaKKs Clutches and Brakes

Wichita AquaMaKKs clutches and brakes are water cooled to allow for high thermal capacities. AquaMakks units utilize composite water jackets to reduce weight, improve water flow and resist corrosion. Copper alloy wear plates provide excellent heat dissipation and consistent tension.

Torque range – 55,440 to 1,596,000 lb-in (6,259 to 180,188 Nm)

Typical applications – Drilling rigs, Deck Equipment, Coilers, Slitters and Lumber Processing Equipment

Kopper Kool Brakes

- Copper disc design for high heat dissipation

- Accurate control

The Wichita Kopper Kool airtube disc Clutches and Brakes are liquid cooled and consist of a series of alternating discs connecting an inner drive member to an outer drive member.

Engagement is achieved by pneumatic expansion of the airtube. This air-operated clutch contains copper discs for excellent heat dissipation and provides an accurately controlled continuous slip action for constant web tensioning. Tension levels are in direct

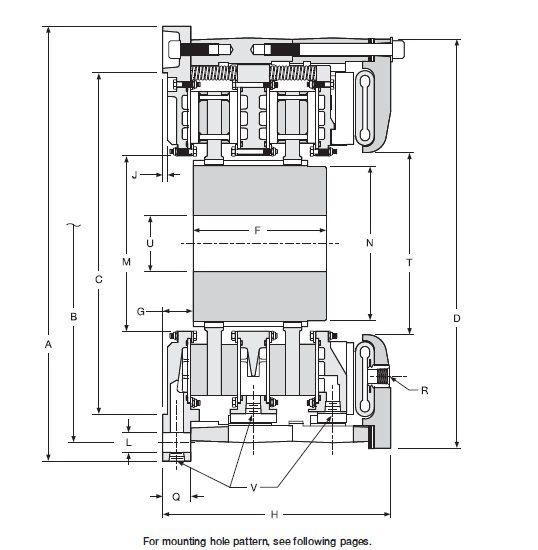

Water-Cooled Clutches and Brakes

Eaton Airflex water-cooled brakes are disc type, externally cooled units. These brakes can dissipate a large amount of heat and are available in a variety of models and sizes. Both spring-applied and air-applied options are available to suit your application.

Torque range: 2,700 to 2,830,000 lb-in (305 to 319,507 Nm)

Typical applications: Paper mills, drawworks, winches, mooring systems, dynamometers