Caliper disc brakes are ideally suited for most large torque, high energy stopping applications. By proper choice of actuating pressure, number of calipers per disc, number of discs and disc diameter a braking system can be custom designed for most applications.

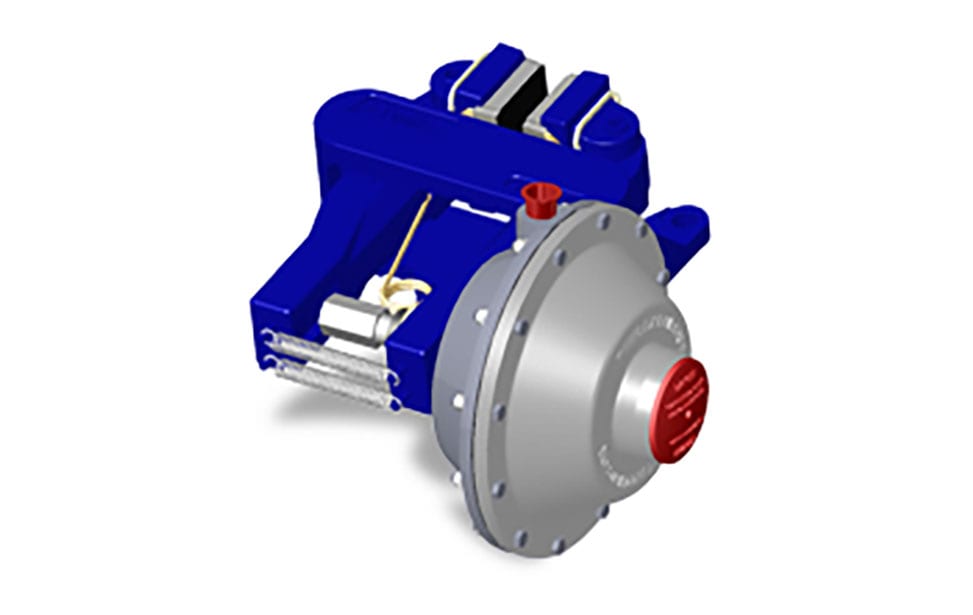

A SERIES HYDRAULIC CALIPER BRAKES

Coremo A series brakes from Clutch Engineering can be fitted with special linings that are twice the size of standard lining options. This provides a larger surface area for the products and increases thermal capacity. Along with other Coremo models, they are available in either spring-applied or hydraulic-applied versions. With spring-applied caliper brakes, emergency stopping capabilities can be added to your equipment. This installation option employs the use of spring-applied braking pressure for use as a fail-safe measure. This option enhances the overall safety of your machinery and operations. Braking force: 1,326 to 3,594 lbf (5,900 to 15,987 N) Typical applications: Steel processing, conveyors, wind turbines, amusement rides, marine propulsion

AIR CALIPER DISC BRAKE

Clutch Engineering offers Kobelt air disc brakes as a rugged and durable air caliper disc brake solutions. These products give dependable control in either air- applied or released designs. The brakes will last in the harshest conditions, due to their construction of bronze and stainless steel. In these products, low pressure actuators with large areas are used to apply the force against a mechanical lever, multiplying the brake application forces with a lever ratio of approximately 3.6:1 and up to 5:1. Easy maintenance is a focal point of the design. This helps to reduce downtime. Torque – 250 to 93,000 ft-lbs Typical applications – Draw-works, hoists, winches, marine propulsion

B SERIES PNEUMATIC CALIPER BRAKES

Available from Clutch Engineering, these Coremo Ocmea B series caliper brakes are high-quality brake products that are available in air-applied or spring-applied versions. In order to ensure safe and satisfactory performance, these calipers are designed to handle the mechanical and thermal stresses of many difficult use cases. The different available options for air-actuation and spring-actuation give your opportunities to create fail-safe systems. When including a fail-safe capability within your system, you can take advantage of having a brake that can engage in the absence of air pressure, which can be critically important when considering the safety of a mechanical system. Braking force: 150 to 798 lbf (670 to 3,550 N) Typical applications: Steel processing, conveyors, wind turbines, amusement rides, marine propulsion

C SERIES PNEUMATIC CALIPER BRAKES

Clutch Engineering offers Coremo’s C series caliper brakes for adding continuous braking functionality into a great variety of mechanical systems. These brakes are well-suited for tensioning and other applications where continuous braking is required. They have a lever balancing and lining pad alignment system, so they can be installed in any position, These pneumatic caliper brakes are air-actuated and require air pressure no greater than 6 bar to operate as intended. All of these features give you a great degree of flexibility when incorporating this effective and versatile air brake into your existing manufacturing, production, or other machinery processes. Braking force: 1,213 to 5,058 lbf (5,400 to 22,500 N) Typical applications: Steel processing, conveyors, wind turbines, amusement rides, marine propulsion

CALIPER DISCS

Clutch Engineering offers ventilated disks from Kobelt. These ventilated discs are compatible with select Kobelt caliper brakes. Multiple thicknesses and diameters have been created and these can be supplied with rough or custom bores. Additionally, Kobelt offers options for discs with included balancing and copper discs are available.

CDB BRAKE

PT Tech caliper disc brakes (CDB) are available from Clutch Engineering for various braking and fail-safe needs across a multitude of industrial applications. These high-quality brakes are spring applied, electrically released, and they also conform to the new AISE brake standard. CDB0812A caliper disc brakes deliver better performance and they are easier to maintain than the drum brakes they effectively replace. Compared to drum brakes on overhead cranes and other applications, wear adjustments for this product are less frequent. Adjustments are also far easier to perform when they are required. Installation of these brakes requires no modification, as the mounting hole pattern matches current drum brake specifications. Brake torque is adjustable from 100% (100 Ib-ft) down to 50% (50 Ib-ft) and is visually verifiable. Torque range: 65 to 6,000 lb-ft (48 to 4,425 Nm) Typical application: Replaces existing drum brakes on overhead cranes

D SERIES HYDRAULIC CALIPER BRAKES

Available from Clutch Engineering, these Coremo D series brakes are ideal for a variety of critical industrial applications. Hydraulic-applied and spring-applied options are both available to best suit the requirements of your particular systems. There are uses for fail-safe brakes in many applications, especially as a deterrent for the negative effects that power outages can cause while machinery is still in motion. Unchecked motion in machinery can create many safety concerns, especially in low-visibility settings or when an immediate response to a loss of power or hydraulic pressure is needed. Braking force: 1,258 to 3,342 lbf (5,600 to 14,868 N) Typical applications: Steel processing, conveyors, wind turbines, amusement rides, marine propulsion

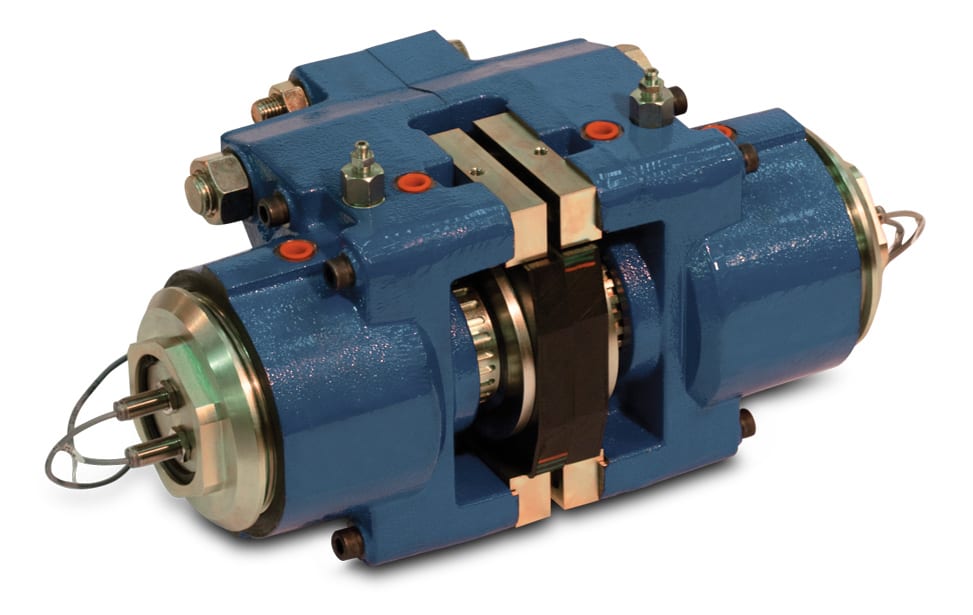

D SERIES PNEUMATIC CALIPER BRAKES

Available from Clutch Engineering, these Kobelt 5300 series disc brakes feature a number of great benefits form their precision construction. Several key features provide ease of maintenance, including a modular actuator design that uses a separable hollow rod cylinder. Brakes also have optional sintered brake pads. This option is useful for high energy applications. Optional release, wear and temperature sensors are also available. These products are ideal for emergency braking duty on draw works, hoists, conveyors and more. They are modular in design for easy installation in a variety of applications. Braking Force – 2,450 to 90,960 lbs Typical applications – Draw-works, hoists, winches, conveyors, marine propulsion

E SERIES PNEUMATIC CALIPER BRAKES

Clutch Engineering offers Coremo E series brakes that are made from high quality ductile iron. The specialized construction of these brakes is designed to withstand the stresses of various challenging use cases. The air-actuated version of this product has a clamping force that varies based on the air pressure supplied to the brake. The spring-applied version functions as a fail-safe product, as the brake caliper will clamp when air pressure is lost. This is important for emergency braking procedures that you install for production equipment and other mechanical systems. Increasing safety with fail-safe brakes is an important step in addressing unforeseen failures that can occur. Braking force: 3,181 to 8,228 lbf (14,150 to 36,600 N) Typical applications: Steel processing, conveyors, wind turbines, amusement rides, marine propulsion

F SERIES HYDRAULIC CALIPER BRAKES

Clutch Engineering offers F series hydraulic caliper brakes for applications that need clamping force to be regulated. For these and other applications, Coremo Ocmea F series hydraulically-actuated brakes are reliable option for your braking needs. For applications that may necessitate the installation of fail-safe braking, such as emergency brakes or holding brakes, F series spring-applied brakes are ready for use. These great products are available in two sizes, to meet your individual braking needs. Spring-applied breaks can be configured to activate in the absence of power to a particular system, which can give you an edge when planning for the safety of your equipment and fail-safe protocol. Braking force: 1,258 to 3,342 lbf (5,600 to 14,868 N) Typical applications: Steel processing, conveyors, wind turbines, amusement rides, marine propulsion

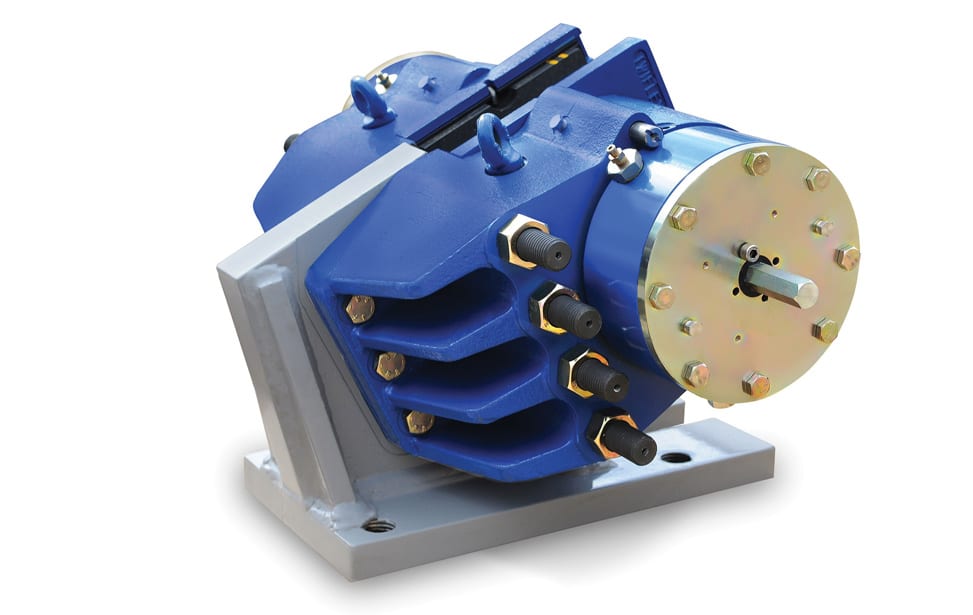

G SERIES HYDRAULIC CALIPER BRAKES

The Coremo G series caliper brake, offered by Clutch Engineering, is perfectly suited for many integral processes within industrial applications. These caliper products have potential applications as emergency braking systems for a diverse array of machinery. The calipers can be fitted with either a hydraulic-applied actuator or a spring-applied actuator. This can be based on the requirements of your machinery. Advanced design and production techniques were used in the creation of these high-quality hydraulic caliper brakes. Braking force: 1,258 to 3,342 lbf (5,600 to 14,868 N) Typical applications: Steel processing, conveyors, wind turbines, amusement rides, marine propulsion

GMR CALIPER BRAKES

Twiflex GMR series caliper brakes have been constructed to meet challenging braking needs that many industries face. Twiflex discs are manufactured from spheroidal graphite cast iron, which is the preferred material, and a range of standard discs in different thicknesses are available from Twiflex. Usually, one or two calipers are used per disc, ideally mounted at 3 or 9 o’clock. Although, with larger diameter discs, more can be used. These great products are available with pneumatically, hydraulically, or spring applied thrusters. Braking force: 1,348 to 8,093 lb (6 to 36 kN) Typical applications: Metals processing, conveyors, grinding mills, wind turbines, amusement rides, marine propulsion

HCDB BRAKE

Available from Clutch Engineering, these PT Tech hydraulic caliper disc brakes (HCDB) are able to replace currently installed hydraulic drum brakes on various pieces of industrial machinery. Compatible machinery includes bridge drives, as these HCDB brakes are similar in size to drum brakes currently installed on these systems. While replacing existing drum brakes, these brake parts leave the existing hydraulic components unchanged. Unlike drum brakes, the HCDB provides the same torque per brake in a two-brake system as it does in a one-brake system. The HCDB is wear compensating, and specialty friction pucks are easy to change when the time comes. As a hydraulically actuated caliper disc brake that directly replaces existing drum brakes, there are many industrial opportunities to upgrade existing equipment with this fantastic product. This brake also uses a ventilated disc for exceptional thermal performance. Torque range: 425 to 900 lb-ft (576 to 1,220 Nm) Typical application: Replaces existing hydraulic drum brakes on bridge drives

Hydraulic Caliper Brakes

Clutch Engineering offers Kobelt hydraulic disc brakes that are both rugged and durable. Their rugged and durable construction provides solid and reliable control in air and hydraulic-applied or released designs. Built from die-cast silicone bronze and stainless steel hardware, these brakes will last in the harshest conditions. The majority of related actuators are of the low pressure type. Easy maintenance is a focal point of the design in order to minimize downtime. Even lining wear is achieved with the use of patented balancing links and the standard supplied lining does not contain asbestos. Torque – 500 to 31,000 ft-lbs Typical applications – Draw-works, hoists, winches, marine propulsion

ID2000 HYDRAULIC CALIPER BRAKE

Clutch Engineering offers Coremo Ocmea ID 2000 hydraulic brakes that can operate in a wide range of temperatures. These temperatures reach from -40° to 392° F (-40° to 200° C). This great resilience to fluctuations in heat provides you with additional flexibility when working with extreme environments. High heat applications for this product may be present in steel processing plants other thermally intense scenarios. A useful wear indicator warns when maximum lining pad wear is reached. The brake has an intuitive inductive ON/OFF sensor to indicate opening and closing. Braking force: 10,566 to 44,961 lbf (47,000 to 200,000 N) Typical applications: Steel processing, conveyors, wind turbines, amusement rides, marine propulsion

ID3000 HYDRAULIC CALIPER BRAKE

Clutch Engineering offers Coremo ID 3000 hydraulic brakes. These advanced brake products can operate in a wide range of temperatures, from -40° to 392° F (-40° to 200° C). In terms of the overall wear on these brakes, a wear indicator warns when maximum lining pad wear is reached. The brake has a useful inductive ON/OFF sensor to indicate opening and closing. As these brakes are spring applied and hydraulically released, they have applications as fail-safe products to increase the safety of many mechanical systems. Braking force: 44,961 to 60,698 lbf (200,000 to 270,000 N) Typical applications: Steel processing, conveyors, wind turbines, amusement rides, marine propulsion

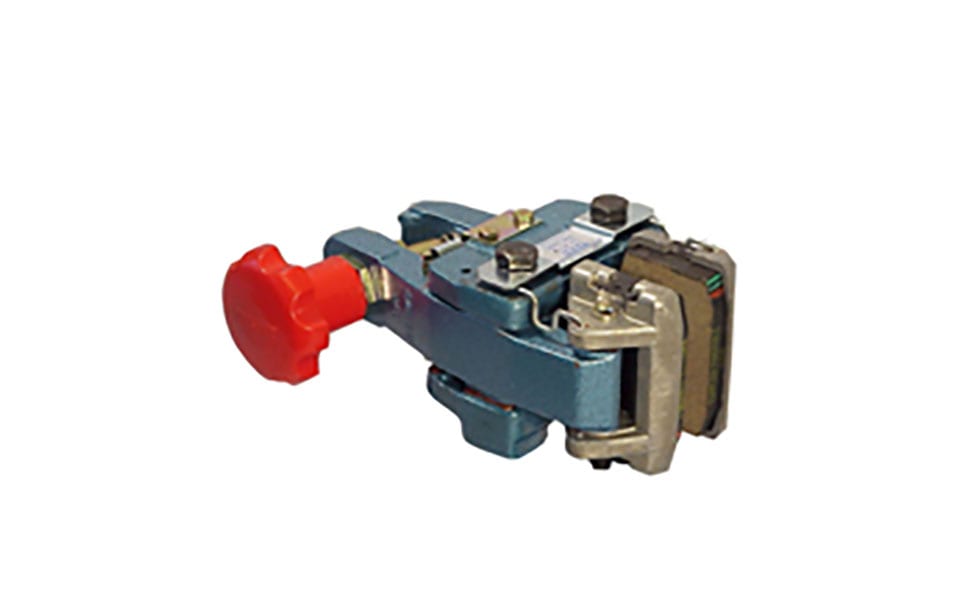

MR CALIPER BRAKES

Clutch Engineering offers Twiflex MR series brake calipers with different actuation choices to meet your requirements. Features such as the brake disc diameter, air pressure, and number of calipers per disc can be altered for your needs. Calipers should Typically, calipers should be mounted horizontally at the 3 or 9 o’clock position around the brake disc. Pneumatic brakes require a control valve, operated either manually or by pneumatic or electrical signal. (Twiflex disc brakes must be used with Twiflex asbestos free brake pads.) Braking force: 166 to 2,427 lb (0.74 to 10.8 kN) Typical applications: Metals processing, conveyors, grinding mills, wind turbines, amusement rides, marine propulsion

MX CALIPER BRAKES

Twiflex MX series brake calipers are precision made to provide braking solutions and fail-safe functionality for a large variety of applications. These brake calipers are available with pneumatic, manual, or spring applied thrusters. Fail-safe spring applied options are available in each of the pneumatic, hydraulic, and electrically released model options. This empowers you to enhance the safety of your systems and meet your failsafe requirements. MX calipers feature a patented link mechanism which ensures uniform pad wear. A range of brake discs are available from Twiflex. Braking force: 166 to 3,214 lb (0.74 to 14.3 kN) Typical applications: Metals processing, conveyors, grinding mills, wind turbines, amusement rides, marine propulsion

T40 CALIPER BRAKES

The Twiflex T40 brake offered by Clutch Engineering is a split caliper with a hydraulically applied design. This lets the brakes be positioned at any angle around the periphery of the disc. Typically one or two calipers are used per disc, but the number may be increased based on the disc size. Modules are mounted at each side of a central mounting plate, which has the same thickness as the brake disc. Braking force: up to 10,116 lb (45 kN) Typical applications: Metals processing, conveyors, grinding mills, wind turbines, amusement rides, marine propulsion

VCS CALIPER BRAKES

The Twiflex VCS is a modular brake caliper offered by Clutch Engineering. This product is both spring applied and hydraulically released, which enables usage as a fail-safe device. The VCS-FL is a single module option, for use when less space is available or to accommodate axial disc float. The brakes may be positioned at any angle around the periphery of the disc, but should ideally be mounted horizontally (i.e. at the 3 o’clock or 9 o’clock position). The two halves (modules) are mounted to each side of a central mounting plate of the same thickness as the brake disc. Braking force: 5,620 to 13,938 lb (25 to 62 kN) Typical applications: Metals processing, conveyors, grinding mills, wind turbines, amusement rides, marine propulsion

VKSD CALIPER BRAKES

Clutch Engineering offers Twiflex VKSD modular brake calipers that are spring applied, hydraulically released, and deliver greater braking force than the VCS. As the brakes are spring applied, there are available uses for this product as a fail-safe device. Applications range from windmills to conveyors, propulsion systems, and amusement park rides. This high-performance product is suitable for use with a minimum disc thickness of 20mm (0.79 in). The two halves (spring modules) are mounted each side of a central mounting plate which is thicker than the brake disc. The Twiflex VKSD-FL disc brake caliper comprises a single spring module forming the ‘active’ side of this floating unit. The VKSD-FL is a single module option, for use where space becomes limited or to accommodate axial disc float. Clutch Engineering offers a great selection of Twiflex brake discs and products. Braking force: 6,295 to 26,752 lb (28 to 119 kN) Typical applications: Metals processing, conveyors, grinding mills, wind turbines, amusement rides, marine propulsion