Clutch Engineering is an authorized Twiflex distributor, for a variety of brake, coupling, and other high-quality mechanical products. We specialize in the distribution of industrial power transmission products, while providing useful technical support for the selection and installation of our mechanical components. We are proud to feature reliable caliper disc brakes from Twiflex, as all of their products reach high-standards of quality and overall functionality. Our Application Engineers can help specify the best braking system for your application, giving you the peace of mind that you are not purchasing any incompatible components. Twiflex, founded in 1946, specializes in the design, manufacture and supply of many advanced braking technologies for various industrial applications. Twiflex offers the largest range of pneumatically-, hydraulically-, and mechanically-applied industrial disc brake calipers in the world (MR, MX, GMR), along with a full line of thrusters, disc brake systems, flexible couplings, and shafts clutch couplings.

Twiflex is a global leader in innovative braking solutions that are designed to provide years of reliable performance. Their huge range of braking products creates an array of mechanical possibilities for a multitude of mechanical systems. Their suite of solutions can be integrated into equipment ranging from cranes, to production machinery, and more. Their attention to detail and performance results in highly-effective product offerings that enhance the capabilities and reliability of equipment across many industries.

Advanced Twiflex solutions are used in many industries, including applications for metals, mining, energy, elevators & escalators, entertainment, conveyors, hoists and cranes, grinding mills, wind and tidal turbines, theme park rides, and propulsion systems. Twiflex parts are also used for marine on applications such as rolling mills. Clutch Engineering can provide long-lasting systems, and expert advice from our application engineers, to cater to the most demanding industrial applications.

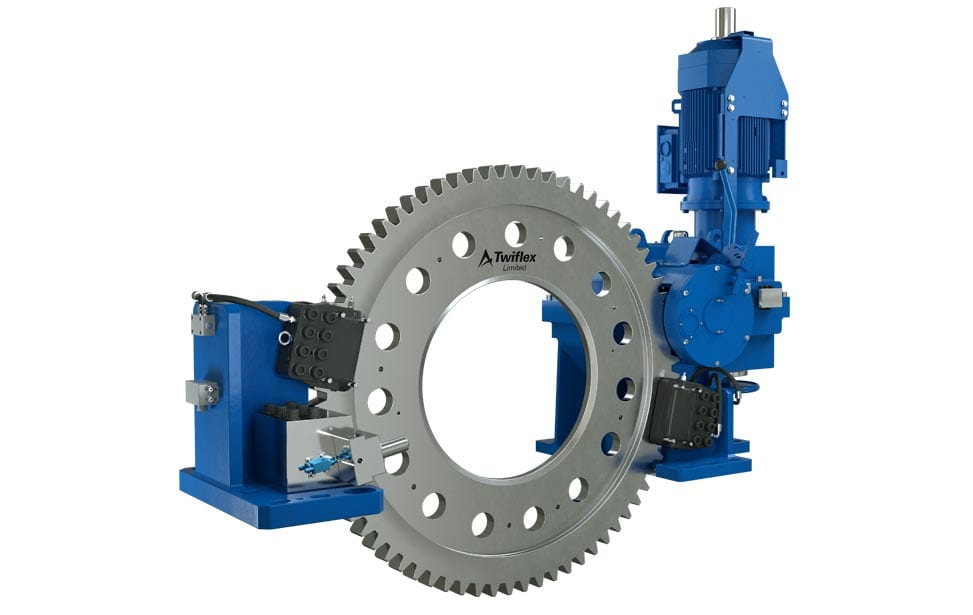

TLB System

The Twiflex Turning, Locking, and Braking System (TLB) is offered by Clutch Engineering and it is constructed with an innovative design that reduces costs. These products reduce the space required for use, and minimize installation and maintenance time, which all supports your bottom line. All three of these important functions, including turning, locking, and breaking, are combined into a single highly-functional system. The useful TLB system is fully designed and built in-house by Twiflex. Additional optional local controls are available.

Turning torques up to 334,850 lb-ft (454,000 Nm)

Braking and locking torques up to 635,780 lb-ft (862,000 Nm)

Typical application: Marine propulsion