Helical gearboxes make use of helical gears and can be used for right angle and parallel shaft applications. Rather than the teeth being parallel to the gear’s axis as in a spur gear, helical gear teeth are cut at an angle.

800 Series Gearboxes

Boston Gear 800 series helical gearboxes are compact and have a long service life. Ratios from 1.5:1 to 250:1 and a variety of input configurations allow 800 series reducers to cover a broad range of applications. Torque range: 288 to 5,423 lb-in (32 to 612 Nm) Typical applications: Material handling, conveyors, metals processing

F Series Gearboxes

Renold’s F Series shaft mounted gear units are available in reduction ratios up to 5,600:1. A wide variety of mounting options and ratios are available. F series gear units are available as motorized, motor-ready, or as a reducer with a keyed input shaft. Torque range: up to 12,170 lb-ft (16.5 kNm) Typical applications: Conveyors, pumps, textile machinery, paper mill machinery

F Series Gearmotors

SEW-Eurodrive F series parallel-shaft helical gearmotors are especially slim to fit where space is limited. Various mounting positions, sizes, and designs ensure that F series gearmotors can cover many applications. Torque range: 95 to 13,275 lb-ft (130 to 18,000 Nm) Typical applications: Conveyors, material handling, steel mills, paper mills

K Series Gearboxes

Renold K Series right angle helical bevel gear units are available in reduction ratios up to 35,000:1. A wide variety of mounting options and ratios are available. K series gear units are available as motorized, motor-ready, or as a reducer with a keyed input shaft. Torque range: up to 24,340 lb-ft (33 kNm) Typical applications: Conveyors, pumps, textile machinery, paper mill machinery

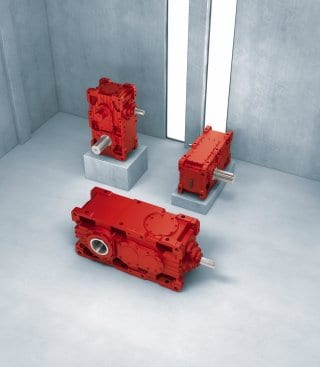

MC Series Gearboxes

SEW-Eurodrive MC series helical and helical-bevel gearboxes are available in eight compact sizes. The MC series uses a modular design with high torque density. Torque range: 4,416 to 47,500 lb-ft (5,987 to 64,401 Nm) Typical applications: Material handling, mixers, overhead cranes, shredders

R Series Gearboxes

Renold’s R Series in-line helical gear units are available in reduction ratios up to 16,200:1. A wide variety of mounting options and ratios are available. R series gear units are available as motorized, motor-ready, or as a reducer with a keyed input shaft. Torque range: up to 14,751 lb-ft (20 kNm) Typical applications: Conveyors, pumps, textile machinery, paper mill machinery

R Series Gearmotors

SEW-Eurodrive R series helical gearmotors have high torque density and long service life. A wide range of torques and gear ratios are offered. Torque range: 36 to 13,275 lb-ft (50 to 18,000 Nm) Typical applications: Steel mills, paper mills, conveyors, waste water treatment

X Series Gearboxes

SEW-Eurodrive X series helical and helical-bevel gearboxes feature an extremely robust housing with flexible mounting options. This design’s high power density allows for reduced costs and weight. Torque range: 5,015 to 350,342 lb-ft (6,800 to 475,000 Nm) Typical applications: Conveyors, ball mills, agitators, overhead cranes, shredders