Clutch Engineering is an authorized distributor of SEW-Eurodrive parts. We specialize in the identification and distribution of high-quality industrial power transmission products that are needed for industrial equipment found around the world. We are proud to feature well-made gearboxes and gearmotors from SEW-Eurodrive as a part of our product lineup. Our knowledgeable staff of applications engineers can help to define the best mechanical solutions for your system, so you can be confident that you are purchasing the right parts to reach your goals. SEW-Eurodrive is a world leader in drive technology and a pioneer in drive-based automation. They have established a reputation for quickly solving the most difficult power transmission and motion control challenges, and we bring that expertise to you in the form of advanced gearmotor systems. They introduced the gearmotor in 1931, and in the 80-plus years since then, they have been developing the very best in drive technology. SEW-Eurodrive also offers the broadest product line in the industry. Products include gearmotors (R, F, K Series) and heavy industrial gear units (X and MC Series) to electronic drives, software, and complete drive-based automation systems.

SEW products are based on a unique and useful system of modular components. These components can be assembled into millions of different configurations, which makes it possible for every drive solution to be custom built to exact customer specifications. Every product offered by SEW-Eurodrive is finely tuned to meet real world needs with effectively and reliably. These products are supported by years of design and testing experience, so you know you are getting high quality, proven part solutions. These product offerings can be easily integrated into many compatible mechanical systems.

For various production processes and equipment needs, SEW-Eurodrive has solutions that add features and capabilities to your processes. Gear reducers manufactured by SEW-Eurodrive are suitable for a wide variety of mechanical applications. Whether systems are built for steel and paper mills, conveyors, ball mills, or overhead cranes, Clutch Engineering can provide these rugged and dependable units to meet your exacting requirements. Contact our team for more information about available products and how we can provide your ideal mechanical product solutions.

F Series Gearmotors

SEW-Eurodrive F series parallel-shaft helical gearmotors are especially slim to fit where space is limited. Various mounting positions, sizes, and designs ensure that F series gearmotors can cover many applications.

Torque range: 95 to 13,275 lb-ft (130 to 18,000 Nm)

Typical applications: Conveyors, material handling, steel mills, paper mills

K Series Gearmotors

SEW-Eurodrive K series helical-bevel gearmotors have gear efficiency of over 90% in both directions of rotation. They’re designed for wear-free operation, allowing for a long service life. As with other SEW Eurodrive products, these gearmotors are compact and have high power density.

Torque range: 59 to 36,878 lb-ft (80 to 50,000 Nm)

Typical applications: Conveyors, material handling, steel mills, paper mills

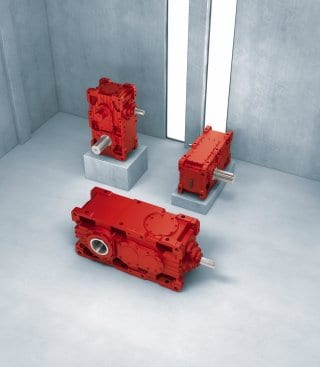

MC Series Gearboxes

SEW-Eurodrive MC series helical and helical-bevel gearboxes are available in eight compact sizes. The MC series uses a modular design with high torque density.

Torque range: 4,416 to 47,500 lb-ft (5,987 to 64,401 Nm)

Typical applications: Material handling, mixers, overhead cranes, shredders

R Series Gearmotors

SEW-Eurodrive R series helical gearmotors have high torque density and long service life. A wide range of torques and gear ratios are offered.

Torque range: 36 to 13,275 lb-ft (50 to 18,000 Nm)

Typical applications: Steel mills, paper mills, conveyors, waste water treatment

X Series Gearboxes

SEW-Eurodrive X series helical and helical-bevel gearboxes feature an extremely robust housing with flexible mounting options. This design’s high power density allows for reduced costs and weight.

Torque range: 5,015 to 350,342 lb-ft (6,800 to 475,000 Nm)

Typical applications: Conveyors, ball mills, agitators, overhead cranes, shredders