Drum clutches and brakes transfer torque by clamping on the outside diameter of a drum. This provides maximum torque per brake radius. Eaton Airflex drum brakes feature an expanding air bladder which clamps onto the full drum circumference.

CB Clutches and Brakes

The Eaton Airflex CB element assembly is air-actuated, with a neoprene rubber air tube providing the clamping force. Friction shoes mounted on the tube’s inside diameter engage around a cylindrical drum. In this design, the rubber air tube is bonded to the outer steel rim.

Torque range: 360 to 260,000 lb-in (41 to 29,400 Nm)

Typical applications: Metal forming, printing, oil and gas, rubber processing

CS and CSA Drum Brakes

Available from Clutch Engineering, the Eaton model CS and CSA brakes are used for conveyor systems, draglines, hoists, stamping presses, and other mechanical systems. These products are well-made spring set, air released brakes. The spring applied braking capability, combined with their responsiveness, makes them a great fit for many emergency braking applications. These specially designed brakes are unidirectional, meaning their braking torque is greatly reduced in the reverse direction. The spring applied brakes automatically engage upon loss of release pressure, for the enhanced safety of your mechanical systems. Automatic engagement and a low releasing volume requirement creates a very responsive brake that provides maximum operator and equipment protection. Torque range: 3,000 to 27,000 lb-in (339 to 3,050 Nm) Typical applications: Conveyors, draglines, hoists, stamping presses

Centric Centrifugal Clutches

Clutch Engineering offers Boston Gear Centric Centrifugal Clutches (CCC) that are compatible with many applications for soft starts, or, conversely, to brake runaway systems. These extremely efficient clutches can function without the need for external controls. All CCC series clutches are custom designed to best fit your application, giving you great freedom to meet the needs of your systems. The spring controlled centrifugal clutch lets engines warm up before starting the load or to stand by at an idling speed, when it is used with engine drives. Due to this ability, the spring controlled centrifugal clutch is highly useful for industrial applications such as dual drives and engine driven pumping systems. Power range: 40 to 2,280 HP (29 to 1,700 kW) Typical applications: Turbines, generators, elevators, conveyors, pumps

E Clutches and Brakes

Offered by Clutch Engineering, the Eaton Airflex type E element assembly is used for construction equipment, marine winches, metalworking machinery, and other industrial applications. This brake is designed to actuate by applying air to an expanding air bladder. Integrated leaf springs are used to resist centrifugal forces and make sure that the friction shoes disengage. To operate effectively, Airflex expanding elements concentrate the frictional force on the inside drum diameter. With this method, this product achieve maximum torque. The torque lever arm is the drum radius, not a reduced radius as occurs in plate clutches. Additionally, not only is the force generated at the optimum radius, but it is also applied uniformly around the drum circumference. Torque range: 11,300 to 225,000 lb-in (1,280 to 25,400 Nm) Typical applications: Construction equipment, marine winches, metalworking

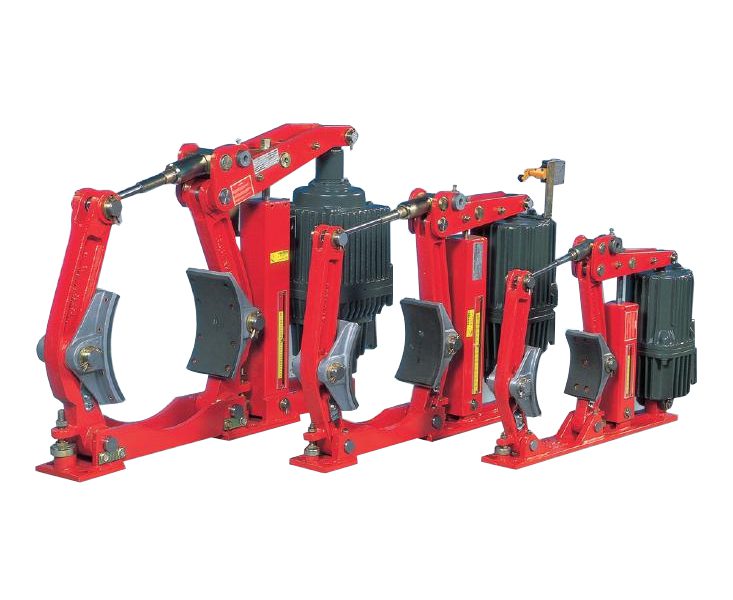

EBN Brakes

Pintsch Bubenzer EBN series drum thruster brakes operate according to the DIN 15435 standard. Bushings are self-lubricating and do not require greasing. A range of thrusters are available to suit your application.

Torque range: 221 to 5,103 lb-ft (300 to 6,920 Nm)

Typical applications: Overhead cranes, mining, steel mills

NLS Centrifugal Clutches

Available from Clutch Engineering, these Boston Gear NLS centrifugal clutches are compatible with many applications that include turbines, generators, elevator systems, conveyor systems, and pumps. The NLS centrifugal clutch is a rugged time-proven unit. When used with various industrial mechanical systems, this product allows systems to be started without load. In addition to aiding in the startup process, these clutches can protect against shock loads by slipping when overloaded. NLS centrifugal clutches are available in both free engagement and delayed engagement versions. When installed, this product is adept at allowing the motor or other driving source to accelerate to operating speed without load and to slipping automatically when overloaded. Power range: 0.2 to 8,360 HP (0.15 to 6,234 kW) Typical applications: Turbines, generators, elevators, conveyors, pumps

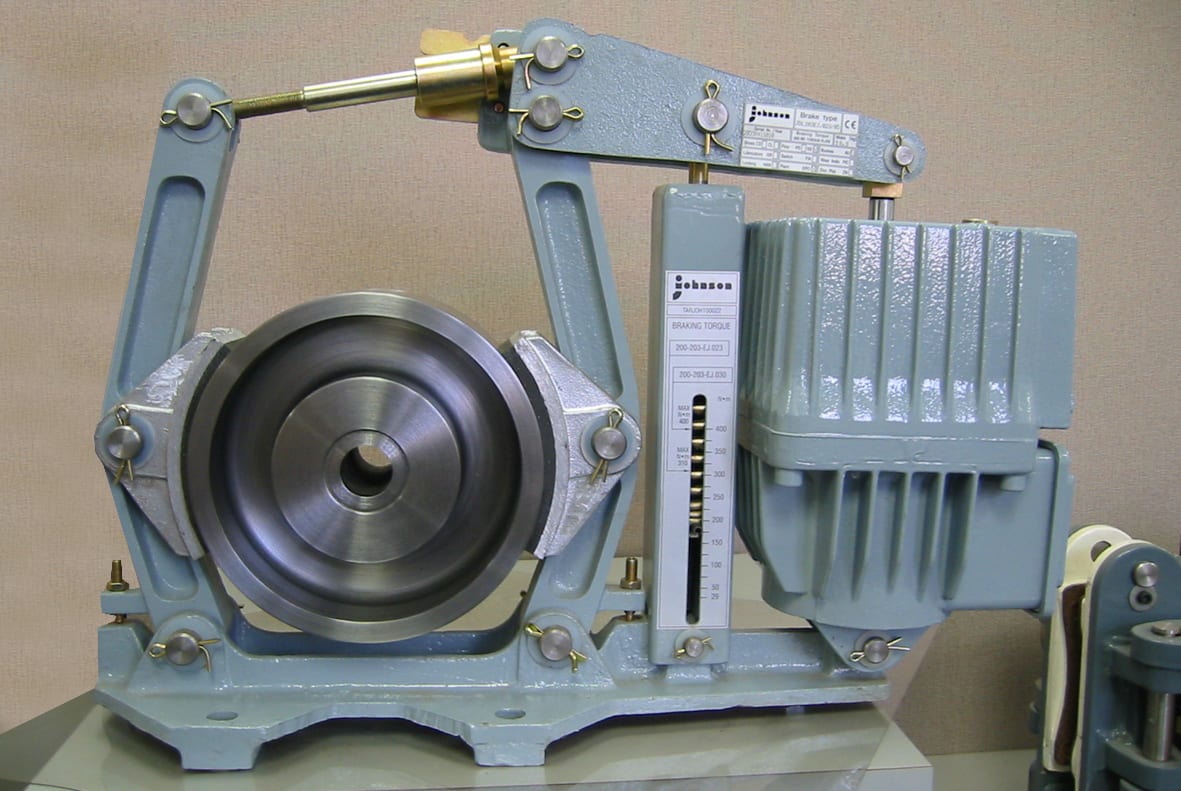

SMLB Thruster Brakes

Johnson SMLB thruster brakes are sturdy and reliable parts, offered by Clutch Engineering. These are commonly used for cranes, conveyors, ski lifts, and other mechanical applications. These thruster brakes are made with reliable fabricated steel components and asbestos-free friction linings that can handle high-temperature environments. A variety of additional special options are available, such as optional mechanical release levers, high temperature assemblies, and explosion-proof designs for your specific needs braking needs. Torque range: 58 to 8,475 lb-ft (78 to 11,490 Nm) Typical applications: Cranes, winches, stacker reclaimers, conveyors, ski lifts

Torque Limiting Coupling

Available from Clutch Engineering, these Eaton Airflex’s Torque Limiting Coupling (TLC) is designed specifically for use in grinding mills of various sizes and capacities. This product is able to protect your grinding mill’s driveline from overloads, which can be a critical part of your overall system safety. As an added benefit, the TLC is reset instantaneously, which reduces equipment downtime. This is a marked improvement on most conventional torque limiting systems. Slip detection control monitors the system and will automatically disengage the TLC if necessary. Experience the benefits of continuously torque monitoring to prevent overload of the motor and damage to costly equipment. When this solution resets and restarts instantaneously, this delivers maximum uptime for your mill operation, which further supports your bottom line. Slip torque range: 3,400,000 to 11,700,000 lb-in (384,148 to 1,321,922 Nm) Typical application: Grinding mills

VC Clutches and Brakes

The Eaton Airflex VC element assembly is an air-actuated constricting drum unit. The VC’s ventilated design allows rapid heat dissipation. The torque is carried by torque bars, and leaf springs retract the friction shoes when air pressure is released. Because of this construction, all components are available as replacement parts when refurbishing the unit.

Torque range: 27,000 to 3,660,000 lb-in (3,050 to 413,057 Nm)

Typical applications: Grinding mills, marine propulsion, metal forming machinery

VE Clutches and Brakes

Available from Clutch Engineering, the Eaton Airflex type VE element assembly is compatible with many mechanical applications, including construction equipment systems, maring winches, metalworking systems, and others. This product is air actuated and it uses a rubber air tube as a part of its construction. The VE has an open design which allows better air flow to help cool the unit when it is in use. To operate, Airflex expanding elements concentrate the frictional force on the inside drum diameter thereby achieving maximum torque. The torque lever arm is the drum radius, not a reduced radius as occurs in plate clutches. Torque range: 25,500 to 58,500 lb-in (2,880 to 6,610 Nm) Typical applications: Construction equipment, marine winches, metalworking