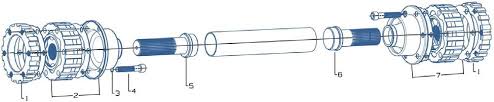

Constant velocity driveshafts provide true constant velocity of the input, intermediate, and output shafts. CV driveshafts aren’t prone to the angular accelerations or vibrations that can be generated by cardan driveshafts.

Constant Velocity Joints

Con-vel constant velocity joints provide true constant velocity. These driveshafts experience no change in velocity or acceleration, smoothly transmitting torque even when joint angles are unequal. Torque range: 169 to 4,725 lb-ft (230 to 6,410 Nm) Typical applications: Steel mill machinery, paper mill machinery, dynamometers, marine propulsion

UF Joints (Fixed)

GKN Lobro RF constant velocity joints allow shaft angles up to 40° and are fixed, providing no axial movement. Length compensation is possible through use of a splined shaft joining the fixed joints. RF fixed joints provide constant angular velocity, even when the input and output angles aren’t equal. Torque range: 427 to 7,744 lb-ft (580 to 10,500 Nm) Typical applications: Steel mill machinery, paper mill machinery, dynamometers, marine propulsion

VL Joints (Plunging)

GKN Lobro VL constant velocity joints allow shaft angles up to 18°, and can plunge to allow for axial movement. VL plunging joints provide constant angular velocity, even when the input and output angles aren’t equal. Torque range: 427 to 29,502 lb-ft (580 to 40,000 Nm) Typical applications: Steel mill machinery, paper mill machinery, dynamometers, marine propulsion