146475

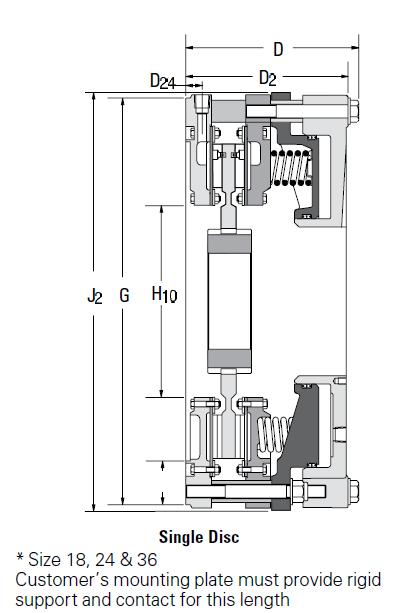

WCB elements are disc type, externally cooled units. They are designed to absorb and dissipate the thermal loads associated with the most severe clutch and brake applications. The WCB friction couple was developed specifically for continuous slip service and has a dynamic coefficient of friction that is greater than its static coefficient of friction. Also available, special high coefficient linings, which provide 50% higher torque than standard friction linings and provide a 1:1 dynamic to