Size

|

114WCB |

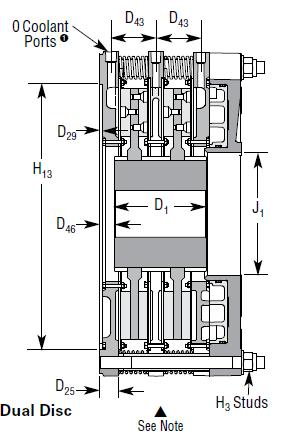

Dimenson D24

|

0.91 in

23 mm |

Dimenson D25

|

1.41 in

36 mm |

Dimenson D29

|

0.250 in

6.4 mm |

Dimenson D46

|

N/A |

Dimenson D43

|

2.90 in

74 mm |

Dimenson G1

|

18.750 in

476.3 mm |

Number of Bolt Holes H3

|

8 |

Bolt Hole Size H3

|

3/4-10 in

3/4-10 mm |

Bolt Circle Diameter H32

|

17.000 in

431.8 mm |

Dimension H10

|

7.12 in

181 mm |

Dimension H133

|

14.375 in

365.1 mm |

Dimension J1

|

6.00 in

152 mm |

Dimension J24

|

18.94 in

481 mm |

Number H4

|

3 |

Size H4

|

3/8-16 in

3/8-16 mm |

Bolt Circle H4

|

6.500 in

165.1 mm |

Small Piston Inlet Thread Size O2

|

1/2-14 in

1/2-14 mm |

Large Piston Inlet Bolt Circle Diameter

|

13.25 in

337 mm |

Small Piston Inlet Thread Size O2

|

3/8-18 in

3/8-18 mm |

Small Piston Inlet Bolt Circle Diameter

|

8.250 in

210 mm |

Minimum Bore Size

|

2.25 in

57 mm |

Maximum Bore Size

|

4.50 in

114 mm |

Dimension D1

|

8.00 in

203 mm |

Dimension D2

|

6.59 in

167 mm |

Number of Coolant Ports O5

|

4 |

Coolant Port Thread Size6

|

1/2-14 NTP |

Gear Part Number

|

415454 |

Dynamic Torque Rating7

|

21500 lb-in @ 80 psi

2429 Nm @ 5.5 bar |

Dynamic Torque Rating – Large Piston Only

|

1808 Nm @ 5.5 bar |

Dynamic Torque Rating – Small Piston Only

|

610 Nm @ 5.5 bar |

Thermal Rating8

|

60 hp

44.7 kW |

Water Flow9

|

6 gpm

22.7 dm³/min |

Maximum Slip Speed10

|

1260 rpm |

Maximum Free Wheeling Speed11

|

2100 |

Housing Weight

|

217 lb

98 kg |

Disc Gear Weight

|

2248 |

Housing Inertia

|

64 lb·ft²

2.7 kg·m² |

Disc Gear Inertia

|

0.276.4 |

Water Volume

|

40 in³

0.7 dm³ |

Manufacturer

|

Eaton-Airflex |

Actuation

|

Air Applied |

Where Used

|

Drilling rigs

Dynamometer

Logging equipment

Marine mooring systems

Slip clutches

Tension brakes

Unwind stands |

Features

|

Patented piston design

Single or dual piston provides wider range of applied tension with greater control.

Drop in powerhead package

Standard single piston elements can be retrofitted with a dual piston powerhead to provide increased control.

Split wear spacers

The split wear spacers allow for wear adjustment without disassembly of the brake to minimize downtime and maintenance costs.

Unique friction couple

A specially formulated friction material, interfacing with a copper alloy surface, eliminates the stick-slip characteristic associated with ordinary frictional devices.

Rapid heat dissipation

The copper interface conducts heat rapidly to the circulating coolant.

Open or closed loop coolant systems

The element works equally well with open or closed loop circulating systems. On mobile equipment, the engine’s cooling system can be tapped to provide coolant to the element.

Optional corrosion protection

For marine environment applications, protective coatings are available to minimize corrosion |