146341

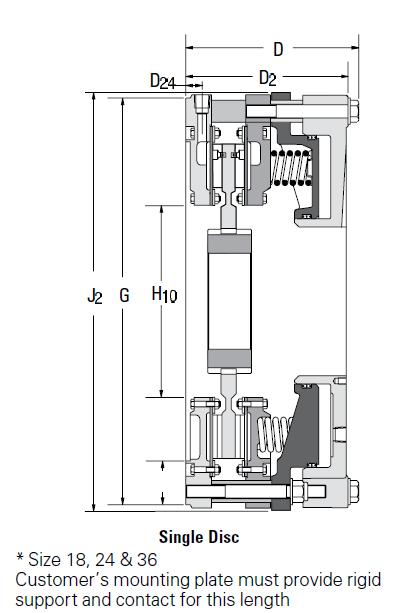

Element construction and operation is illustrated in the figure. Pressurizing the unit compresses the brake springs and withdraws the water jackets from the brake discs. Heat generated at the friction interfaces is quickly transferred to the circulating coolant.

Element sizes are indicated by the number of friction discs and the disc diameter in inches. For instance, size 224WCS has two friction discs 24 inches in diameter.