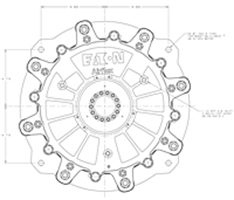

138FHB

Typical Applications

Draglines

- Hoist

- Drag

- Swing

- Propel (Walk)

Electric Shovels

- Hoist

- Crowd

- Swing

- Propel

Winches

Features

Large friction area.

Rated for over 430,000 lb-in of torque

Patented braking concept uses a floating housing instead of a floating rotor

Multiple brake installation designs exist for industry leading motors

Fixed hub and rotor design

Minimal adjustment required for lining wear.

Single disc units require no wear adjustment and dual disc units require only one wear adjustment during the long life of the friction material.