Torsional couplings are flexible couplings that offer a number of benefits to mechanical systems. These couplings can protect your driveline and increase the life of downstream equipment by dampening vibration. Additionally, torsional couplings operate as flexible couplings by design. This feature helps them to compensate for radial, axial, and angular misalignment. For additional information about torsional couplings, contact our team directly.

Dura-Flex Couplings

TB Wood's Dura-Flex couplings are manufactured with precision and available from Clutch Engineering. The element is light weight and absorbs shock loading and torsional vibration. These high-performance coupling products have a two-piece element that makes installation easy. This ease of installation can also reduce the downtime of your machinery, for the benefit of your bottom line. Coupling must be guarded, both to prevent any contact with the rotating parts and to contain the coupling components should they fail. Torque range: 190 to 39,500 lb-in (21 to 4,462 Nm) Typical applications: Pumps, agitators, conveyors, paper mills, shredders, cranes

HTB Couplings

Clutch Engineering offers Renold HTB couplings, which are designed for bell housing applications and are intrinsically fail-safe for critical applications. These products offer advanced protection against severe shock loads, and no lubrication or adjustment is required. These features result in lower running costs and increased machinery uptimes. These couplings can also handle temperatures up to 400° F (200° C). An additional benefit is that these products can ensure continuous operation of the driveline in the unlikely event of rubber damage. Torque range: 885 to 29,500 lb-ft (1.2 to 40 kNm) Typical applications: Marine propulsion, compressors, generator sets, pumps, rail traction

Megiflex B Coupling

Clutch Engineering offers the Megliflex B coupling by American Vulkan, for use with marine propulsion systems, auxiliary drives, and other mechanical systems. This is a very versatile coupling with an advanced modular construction that is designed with a fail-safe functionality. This coupling is also torsionally soft and has high misalignment capabilities to meet the unique needs of many systems. The Megliflex B is available in 15 sizes, each with 2 rubber stiffness classes. These sizes and classes can be either radially assembled or plugged in axially depending on the series. In addition to the compact design, the double cardanic Megliflex B series is versatile as a highly displacing and torsionally flexible drive shaft. This enables these products to be used for a broad range of installation needs. Torque range: 7 to 2,304 lb-ft (0.010 to 3.125 kNm) Typical applications: Marine propulsion, auxiliary drives

Periflex Couplings

Available from Clutch Engineering, these Periflex couplings from Stromag are high-quality products that can be used in many industrial systems. Mechanical systems can benefit from these flexible rubber couplings, particularly when internal combustion engines are present. The Periflex VN is flanged to mount directly to standard flywheels. The Periflex CS is specially designed to connect an engine flywheel to a cardan shaft flange. Periflex shaft couplings can be used throughout the full temperature range of -50°C to +80°C. The Stromag Periflex shaft coupling is a highly flexible rubber-fabric coupling that is especially suitable for connecting two shafts in diesel engine and electric drives. Torque range: 18 to 46,466 lb-ft (25 to 63,000 Nm) Typical applications: Steel mills, cranes, conveyors, mining, paper machinery, shipbuilding, construction, PTO's

PM Coupling

Clutch Engineering offers Renold PM flexible couplings for use with pumps, fans, compressors, and other industrial machinery. No lubrication or adjustment is required for these parts, which increased machinery uptime and improves your bottom line. These PM couplings allow for instances of axial, angular, and radial misalignment while reducing vibration and guarding against shock loads. This product can achieve low vibratory loads in driveline components through the selection of optimum stiffness characteristics. A variety of rubber elements are available for optimal performance. This product also seeks to eliminate torque amplifications through pre-compression of the rubber elements. Torque range: 106 to 1,720,976 lb-ft (0.14 to 2,333 kNm) Typical applications: Pumps, fans, compressors, cranes, conveyors

Propflex Couplings

Available from Clutch Engineering, these American Vulkan Propflex couplings can meet a variety of mechanical needs. The Propflex coupling is a flexible displacement coupling, suitable for many different application areas. The design of this product is ideal for isolating driveline vibrations, while reducing noise better than conventional displacement couplings. Torque transmission with simultaneous compensation of displacement occurs through rubber bushes. Through these specially developed rubber bushes, advanced noise-reducing properties are achieved. Propflex couplings can also compensate for radial, axial, and angular misalignment within your system. Torque range: 2,065 to 39,238 lb-ft (2.8 to 53.2 kNm) Typical application: Propeller shafts

Rato Coupling

Clutch Engineering offers American Vulkan Rato couplings for marine propulsion systems, auxiliary drives, generators, and other industrial applications. These dependable couplings are compatible with both flexibly and rigidly mounted engines. They are torsionally flexible and can compensate for instances of radial, axial, and angular misalignment. These products are also designed to achieve maximum heat dissipation and a very long life. With advanced design and construction, torque is transmitted by elements loaded in shear. The different torsional stiffnesses and damping factors, available upon request, provide additional options for satisfactorily tuning the torsional vibration behavior of your drive system. Torque range: 5,900 to 5,900,000 lb-ft (8 to 800 kNm) Typical applications: Marine propulsion, auxiliary drives, generators

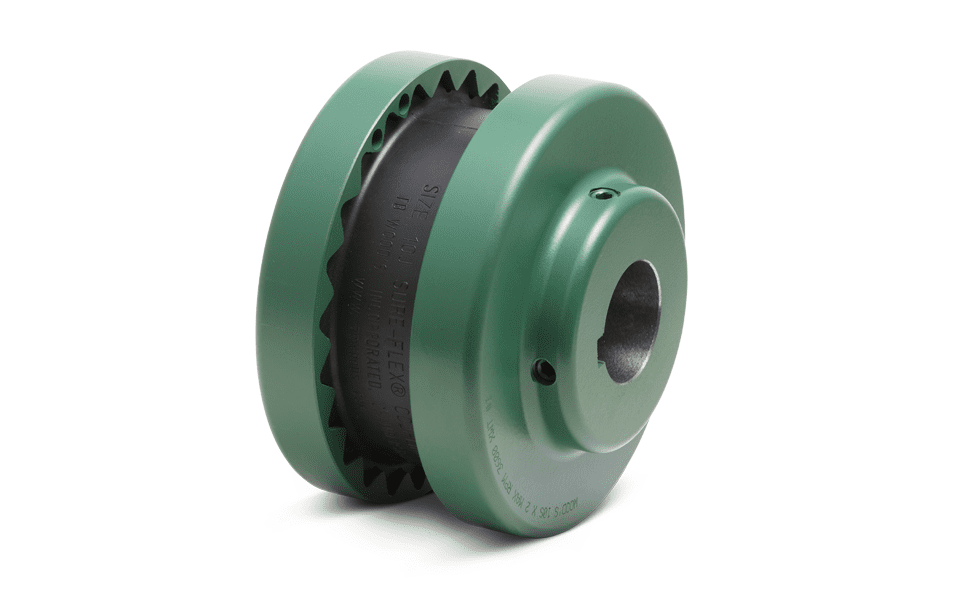

Sure-Flex Couplings

Clutch Engineering provides TB Wood's Sure-Flex couplings for applications such as pumps, generators, hoists, and conveyor systems. These couplings are designed to support the absorption of virtually all types of shock, misalignment, and end float. Minimum shaft engagement is 0.85 * shaft diameter and no lubrication or maintenance is required. The lack of manual lubrication helps you to allocate efforts elsewhere, without needing additional time for the upkeep of this product. Variations of available parts and features include close-coupled, spacer, and split sleeves. These couplings are precisely manufactured to give you an optimal solution for various applications that are compatible with couplings and related variations. Torque range: 78 to 72,480 lb-in (8 to 8,189 Nm) Typical applications: Pumps, generators, hoists, conveyors

Vulastik Coupling

Clutch Engineering offers American Vulkan Vulastik L couplings, which are often used in marine propulsion systems, auxiliary drives, and generator applications. Various styles are available which allow the element to be replaced without moving the adjacent machinery. Four different rubber qualities and an additional option for silicone are available, in order to tune the coupling to your system requirements. These couplings benefit from an extremely compact design that is suitable for efficient engines with high power density. Vulastik L couplings are available with one elastic element in standard design or as dual execution with two parallel elements. Torque range: 383 to 38,353 lb-ft (0.52 to 52 kNm) Typical applications: Marine propulsion, auxiliary drives, generators

Vulkardan Coupling

Clutch Engineering provides American Vulkan Vulkardan couplings for integration into marine propulsion applications, auxiliary drives, generators, and other mechanical use cases. The Vulkardan E coupling is a highly-flexible rubber coupling for free standing installations, which includes use for many free standing industrial and nautical engine applications. This product can reduce torsional vibration in many cases, while accommodating a range of radial, axial, and angular misalignments. Different element properties are also offered for this product, to optimally meet the requirements of your system. The Vulkardan E can effectively solve many alignment challenges, and is able to deliver fantastic performance for flexible mounted engine installations. The Vulkardan F is the successor of the well-established Vulkardan E and complements the VULKAN highly flexible couplings product portfolio below the RATO R torque range. Torque range: 154 to 60,406 lb-ft (0.21 to 81.9 kNm) Typical applications: Marine propulsion, auxiliary drives, generators