Clutch Engineering is an authorized distributor for American Vulkan specialized parts. These parts include couplings, clutches, engine mounts, and more. Clutch Engineering is experienced in the distribution of industrial power transmission products, and we also offer advanced customer service and support to ensure that you are getting the right parts for your needs. Our applications engineers are able to consider your unique mechanical needs when recommending parts that will meet your goals and enhance your processes. We are proud to feature torsional couplings, double-cone clutches, and motor mounts from American Vulkan. American Vulkan’s highly qualified and experienced staff and engineers also ensure that their products are manufactured at the highest industrial quality standards. Established in 1971, American Vulkan Corporation (AVC) is a member of the multinational Vulkan Group.

For use in many advanced systems, a broad range of torsionally flexible couplings (Rato, Vulastik, Vulkardan, Megiflex B, and Propflex), clutches (Meslu), engine mounts (T and VDM series), and monitoring systems (MDS2 and Torvib) are available. These products help dampen drivetrain vibration and increase the efficacy of your mechanical systems. Highly skilled staff and engineers ensure that our product offerings are manufactured at the highest industrial quality standards. This quality is passed along to customers in the form of reliable and long lasting products, with benefits that will enhance your bottom line. There are many ways to take advantage of these mechanical solutions to maintain and upgrade your mechanical operations.

American Vulkan products have a successful track record in the marine, industrial, and construction markets, to name a few. Clutch Engineering will work with you to provide optimal product solutions to ensure compatibility with your critical systems. Contact our team for additional information about these solutions and more.

Vulastik Coupling

Clutch Engineering offers American Vulkan Vulastik L couplings, which are often used in marine propulsion systems, auxiliary drives, and generator applications. Various styles are available which allow the element to be replaced without moving the adjacent machinery. Four different rubber qualities and an additional option for silicone are available, in order to tune the coupling to your system requirements. These couplings benefit from an extremely compact design that is suitable for efficient engines with high power density. Vulastik L couplings are available with one elastic element in standard design or as dual execution with two parallel elements.

Torque range: 383 to 38,353 lb-ft (0.52 to 52 kNm)

Typical applications: Marine propulsion, auxiliary drives, generators

Vulkardan Coupling

Clutch Engineering provides American Vulkan Vulkardan couplings for integration into marine propulsion applications, auxiliary drives, generators, and other mechanical use cases. The Vulkardan E coupling is a highly-flexible rubber coupling for free standing installations, which includes use for many free standing industrial and nautical engine applications. This product can reduce torsional vibration in many cases, while accommodating a range of radial, axial, and angular misalignments. Different element properties are also offered for this product, to optimally meet the requirements of your system. The Vulkardan E can effectively solve many alignment challenges, and is able to deliver fantastic performance for flexible mounted engine installations. The Vulkardan F is the successor of the well-established Vulkardan E and complements the VULKAN highly flexible couplings product portfolio below the RATO R torque range.

Torque range: 154 to 60,406 lb-ft (0.21 to 81.9 kNm)

Typical applications: Marine propulsion, auxiliary drives, generators

Rato Coupling

Clutch Engineering offers American Vulkan Rato couplings for marine propulsion systems, auxiliary drives, generators, and other industrial applications. These dependable couplings are compatible with both flexibly and rigidly mounted engines. They are torsionally flexible and can compensate for instances of radial, axial, and angular misalignment. These products are also designed to achieve maximum heat dissipation and a very long life. With advanced design and construction, torque is transmitted by elements loaded in shear. The different torsional stiffnesses and damping factors, available upon request, provide additional options for satisfactorily tuning the torsional vibration behavior of your drive system.

Torque range: 5,900 to 5,900,000 lb-ft (8 to 800 kNm)

Typical applications: Marine propulsion, auxiliary drives, generators

Megiflex B Coupling

Clutch Engineering offers the Megliflex B coupling by American Vulkan, for use with marine propulsion systems, auxiliary drives, and other mechanical systems. This is a very versatile coupling with an advanced modular construction that is designed with a fail-safe functionality. This coupling is also torsionally soft and has high misalignment capabilities to meet the unique needs of many systems. The Megliflex B is available in 15 sizes, each with 2 rubber stiffness classes. These sizes and classes can be either radially assembled or plugged in axially depending on the series. In addition to the compact design, the double cardanic Megliflex B series is versatile as a highly displacing and torsionally flexible drive shaft. This enables these products to be used for a broad range of installation needs.

Torque range: 7 to 2,304 lb-ft (0.010 to 3.125 kNm)

Typical applications: Marine propulsion, auxiliary drives

Meslu Clutches

Available from Clutch Engineering, these American Vulkan Meslu clutches can be used for dredge pumps, marine drives, auxiliary drives, and other mechanical systems. These well-designed clutches are dry-running, pneumatically actuated, and feature a double-cone construction. In these products, friction lining wear is automatically compensated for, better providing you with an ideal clutch solution. They also operate free of backlash and do not produce any axial load. The electrical part comprises the Monitoring Device. This device is able to detect clutch slippage and monitor the twist angle of the highly flexible coupling in order to protect the drive train.

Torque range: 5,900 to 232,332 lb-ft (8 to 315 kNm)

Typical applications: Dredge pumps, marine drives, auxiliary drives

Propflex Couplings

Available from Clutch Engineering, these American Vulkan Propflex couplings can meet a variety of mechanical needs. The Propflex coupling is a flexible displacement coupling, suitable for many different application areas. The design of this product is ideal for isolating driveline vibrations, while reducing noise better than conventional displacement couplings. Torque transmission with simultaneous compensation of displacement occurs through rubber bushes. Through these specially developed rubber bushes, advanced noise-reducing properties are achieved. Propflex couplings can also compensate for radial, axial, and angular misalignment within your system.

Torque range: 2,065 to 39,238 lb-ft (2.8 to 53.2 kNm)

Typical application: Propeller shafts

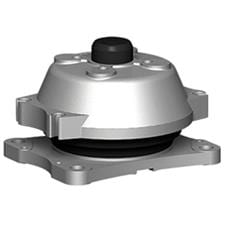

T Series Mounts

Clutch Engineering offers American Vulkan’s T Series mounts, for use with propulsion engines, generator sets, and other industrial systems. Several different versions are available to suit your application and each high-quality mount option is developed for optimal insulation and comfort. All mounts have a built-in centralized limiter, for defense against the challenges of extreme displacements that may result from a ship’s movements while on the water. T series conical mounts developed for marine propulsion engines and generator set suspensions, combine excellent vibration isolation properties with seaway stability and integrated displacement limiter. These products are pre-loaded, available in 13 different sizes and 3 versions to suit your application.

Load range: 900 to 29,450 lbf (4 to 131 kN)

Typical applications: Propulsion engines, generator sets

VDM Series Mounts

Offered by Clutch Engineering, these American Vulkan VDM Series mounts are made with precision and reliability in mind. They ensure insulation and comfort in systems such as ship drives, industrial pumps, large fan units, compressors, and more. A variety of specialized rubber formulations are available, to meet the needs of particular systems. All mounts feature a built-in centralized limiter to defend against extreme displacements that may be encouraged by a ship’s movements. Vibration isolation is used in tandem with thrust transmission for propulsion installations in ST versions. These well-made products are available in 3 sizes and 2 versions with displacement limiter features, as versatile and cost effective suspension solutions. The VDM series mounts were specially developed for propulsion and auxiliary machinery suspension use cases.

Load range: 90 to 1,776 lbf (0.4 to 7.9 kN)

Typical applications: Ship drives, pumps, fans, compressors, generator units

MDS2 Monitoring System

The American Vulkan MDS2 monitoring system, available from Clutch Engineering, can gather data for the optimization and protection of your industrial machinery. This particular system is able to measure the twist angle of couplings or composite shafts within your equipment. MDS2 can be used as a monitoring device to help plan long-term preventative maintenance, or as a safety device when integrated with a clutch. This can create a method for disengaging and protecting the drivetrain from dangerous overload. These systems can offer capabilities that include the monitoring of dynamic vibratory twist angle, drive side and driven side, and torsional amplitudes. These featured capabilities reach up to 30 degrees.

Typical applications: Marine propulsion, auxiliary drives, generators, wind turbines

Torvib Monitoring System

Clutch Engineering offers the American Vulkan Torvib monitoring system, which can be used for marine propulsion systems, auxiliary drives, and various generators. The well-made Torvib system is able to detect and signal engine/motor overloading, resonances and engine misfiring. This monitoring system features multiple functionalities and is capable of measuring either vibratory amplitudes on the flywheel or the vibratory twist angle across a coupling. The system can add great value into your industrial equipment by detecting engine/motor overloading, resonances, and engine misfiring. This device is specially designed to monitor two and four stroke diesel motor/prime mover and shaft lines.

Typical applications: Marine propulsion, auxiliary drives, generators