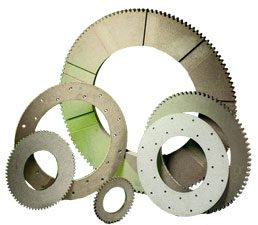

Clutch Engineering offers friction materials with a wide variety of friction coefficients and wear rates. Available formulations can be purchased in flat sheets, flexible rolls, or custom shapes. We reline obsolete friction discs, shoes, and bands upon request. All friction materials we offer are non-asbestos.