142641

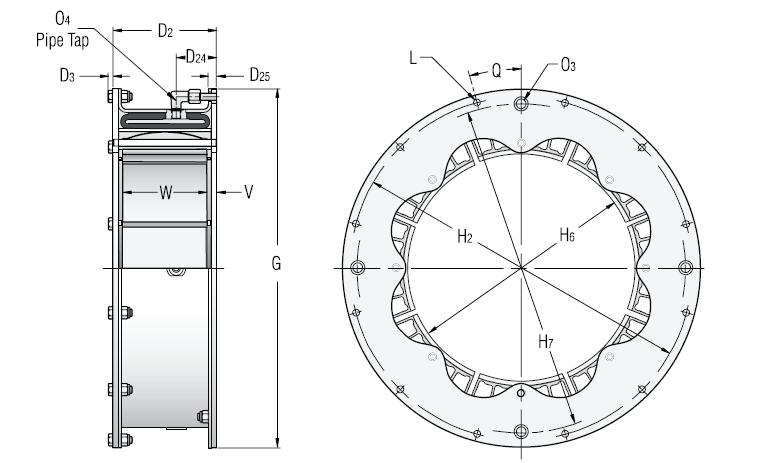

VC design and construction is different from the CB and CM elements in that the torque is transmitted by torque bars rather than the sidewalls of the actuating tube. The loose actuating tube is contained within a housing formed by a rim and two side plates. and is replaceable. The torque bars, which are held in position by the side plates, pass through cavities in the backing plates of the friction shoes. Pressurizing the actuating tube forces the friction shoes to engage around a cylindrical drum. Leaf springs in the torque bar cavities of the backing plates retract the friction shoes when the actuating tube pressure is released. Element torque capacity is dependent upon the applied pressure and rotating speed. Catalog ratings are given at 75 psi (5.2 bar) and zero rpm. Maximum recommended pressure is 125 psi (8.6 bar). Adjustment for

pressure and speed is explained under Selection Procedure.

VC elements are available in 24 sizes which are identified by the drum diameter in inches on which they constrict and the width in inches of its friction lining. For a given drum diameter it is possible to have two different lining widths. For this reason, the elements are grouped by lining width into a narrow series and a wide series. As an example, the narrow series 20VC600 and the wide series 20VC1000 both constrict on a 20 inch diameter drum. But, the narrow unit has a lining width of 6 inches, and the wide unit has a lining width of 10 inches. The smallest VC element will constrict on a 11.5 inch (292 mm) diameter drum and the largest on a 76 inch (1930 mm) diameter drum.

Two elements of a narrow series can be bolted together to form a dual element having twice the torque capacity of a single element. With the exception of the 14VC1000 element, the wide series elements can also be dualed. The large drum hub diameter and small drum diameter restricts the radial space available for mechanically connecting the drums to the hub and makes dualing the 14VC1000 elements impractical.

The VC design offers the following features in addition to the constricting features described earlier in this section.