Worm gearboxes utilize a screw-like worm turning a circular worm gear. Their axes are positioned 90 degrees from each other. Single and double reductions cover a wide range of ratios.

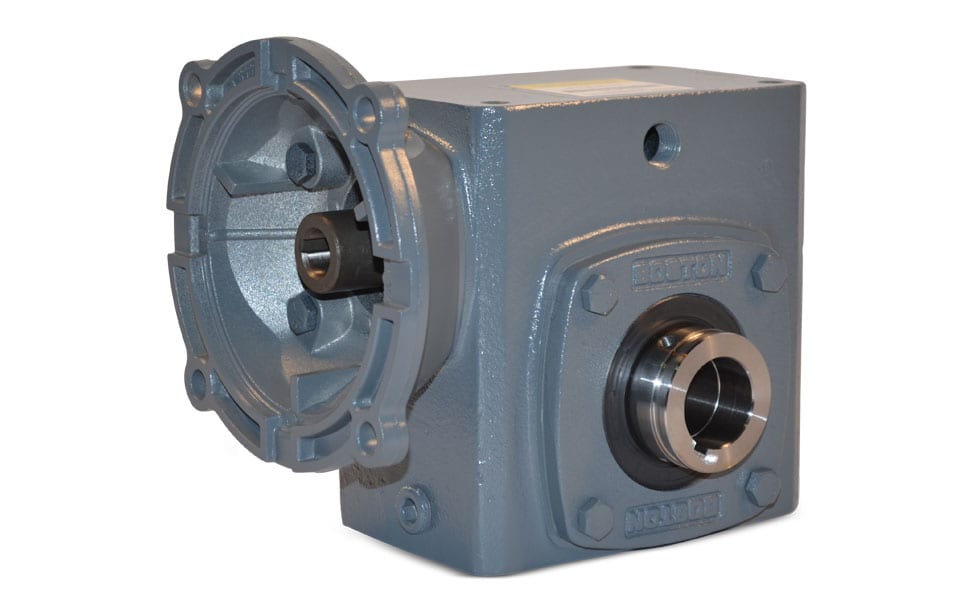

700 Series Gearboxes

Boston Gear 700 series worm gearboxes are available with ratio from 5:1 all the way to 3,600:1. They feature a large oil reservoir for efficient heat dissipation and lubrication. The rugged housing can optionally be coated or made from stainless steel for washdown applications Torque range: 98 to 16,000 lb-in (11 to 1,807 Nm) Typical applications: Material handling, conveyors, metals processing

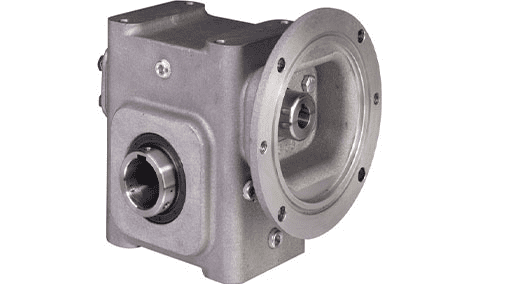

Aluminum EL Series

When size and weight are critical requirements in your power transmission package, the GROVE GEAR® Quadro Aluminum Worm Gear reducer offers an ideal solution. The Quadro is up to one third smaller than alternatives and features an aluminum alloy housing making it a compact and lightweight solution for difficult installations. Torque Rating: 128 – 28,138 lb-in Typical Applications: Material handling, conveyors, metal processing

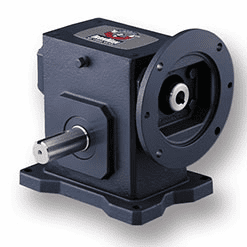

Cast Iron GR Series Ironman

The 800 Series GROVE GEAR® IRONMAN® gear reducer is a true heavy-duty workhorse that handles the environmental assaults, shock loading, frequent reversing and continuous duty cycles typical in many industrial applications. Designed to be the premium worm reducer in the industry, IRONMAN® reducers offer top quality features. Torque Rating: 128 – 88,666 lb-in Typical Applications: Material handling, conveyors, metal processing