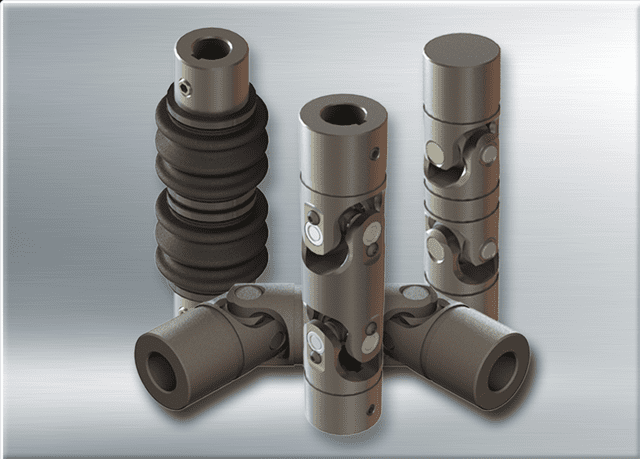

Universal joints are able to transfer torque over a larger misalignment than other flexible couplings. Single joint, double joint, and telescoping shafts are available to fit your application.

Double Universal Joint

Belden Universal’s double universal joints are made to the same exacting standards as their single universal joints. Double universal joints allow for a larger operating angle, and using phased double joints allows for equal input and output speeds, provided operating angles are equal. Torque range: 18 to 5,735 lb-in (2.1 to 648 Nm) Typical applications: Metalworking machinery, printing machinery, conveyors, packaging systems, steering systems, machine tools

Geared Mill Spindles

Renold Ajax geared mill spindles offer high power density and long life. Renold uses a roll end piloting system to reduce bore wear and vibration. Typical applications: Roughing mills, finishing mills

Single Universal Joint

Single universal joints from Belden Universal are more durable and perform better than standard industrial-grade models. Pin and block joints can transmit torques in the most demanding applications. For high-speed applications, needle bearings joints are available. Torque range: 14 to 28,000 lb-in (1.6 to 3,163 Nm) Typical applications: Metalworking machinery, printing machinery, conveyors, packaging systems, steering systems, machine tools

Telescoping Universal Joint

Belden telescoping universal joints are designed specifically to meet the needs of your application. Telescoping length allows for flexibility when mounting. Belden offers a wide variety of materials, coatings, and mounting arrangments to ensure optimal performance. Typical applications: Metalworking machinery, printing machinery, conveyors, packaging systems, steering systems, machine tools