Clutch Engineering is an authorized Warner Electric distributor. We specializes in the distribution of industrial power transmission products, while also offering expert advice to support the selection and integration of parts into mechanical systems. We are proud to feature electric clutches and brakes from Warner. Our Application Engineers provide technical support and can help with product selection, so you can be confident when selecting and purchasing parts from our specialized product lineup. Founded in 1927, Warner Electric has grown to become a global leader in the development of innovative electromagnetic clutch & brake solutions. Warner Electric engineers utilize the latest materials and manufacturing technologies to design equipment for long life and easy usability. These clutches and brakes provide improved accuracy and repeatability in many mechanical systems.

Warner Electric stands out for offering the broadest selection of industrial clutches (SF and SFC Series), brakes, clutch/brake combinations (CB and EM series), controls and web tension systems, out of any single manufacturer. Warner Electric is a market leader in electromagnetic clutch and brake technologies for mechanical needs around the globe. Their high standards of product design and manufacturing quality set them apart from competitors. They address industrial challenges with a diverse set of high-performance products. Their braking and clutch products are compatible with the needs of many industrial processes. They also offer fail-safe braking products for use in scenarios that require emergency braking.

These reliable Warner Electric components are often used in applications for material handling, packaging machinery, food & beverage, elevator & escalator, turf & garden, crane & motion control, agriculture, off-highway, and forklift markets. Additional applications include conveyors, lift trucks, wrapping machines, servo motors, capping equipment, combines, balers, baggage handling systems, military vehicles, hoists and lawn mowers. Clutch Engineering can provide reliable Warner Electric products for your application, with technical support to ensure you are getting parts that will suit your individual needs. Contact us for more information about available products and ways that your mechanical systems can benefit from high-performance clutch and brake solutions.

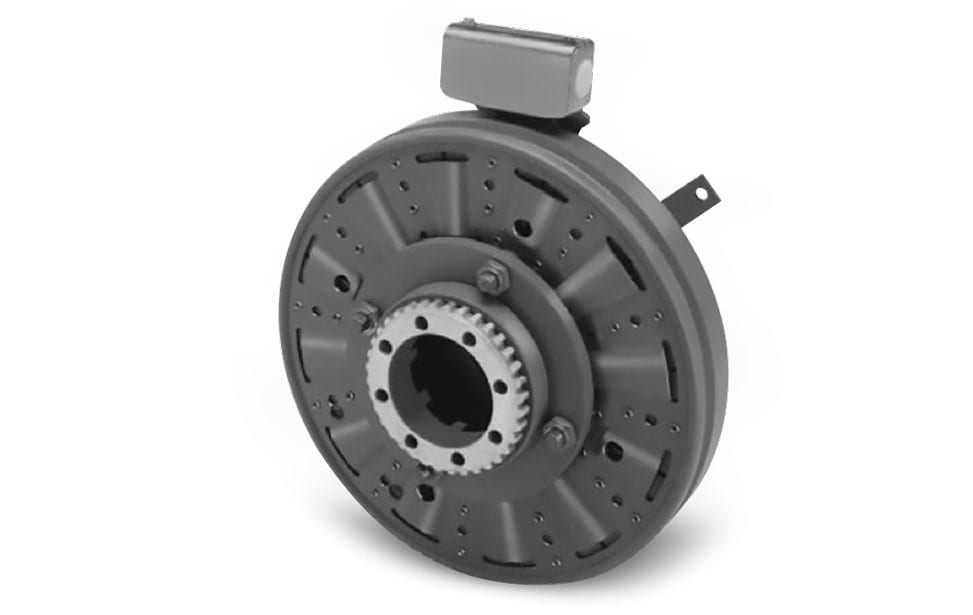

SF Clutches

Clutch Engineering provides Warner Electric SF series clutches for use with a multitude of parallel shaft systems. These well-made parts have a stationary field design, which effectively avoids the necessity for collector rings and brush holders. SF clutches are also resilient enough to operate in many adverse environmental conditions. SF clutches can be flange or bearing mounted, to address your particular mounting needs. The construction of these devices is specially developed to function reliably for many common and critical parallel shaft applications.

Torque range: 5 to 16,200 lb-in (0.5 to 1,830 Nm)

Typical applications: Parallel shaft applications

SFC Clutch Couplings

Offered by Clutch Engineering, these Warner Electric’s SFC series clutch couplings are compatible with a wide range of in-line shaft applications. While they can be used as a coupling for in-line shaft applications, these parts can also be flange or bearing mounted. These clutch couplings have a stationary field design, that avoids a dependency on collector rings and brush holders. SFC clutch couplings are precisely designed to operate within a variety of mechanical use cased to support the specific requirements of your in-line shaft equipment.

Torque range: 5 to 16,200 lb-in (0.5 to 1,830 Nm)

Typical applications: In-line shaft applications

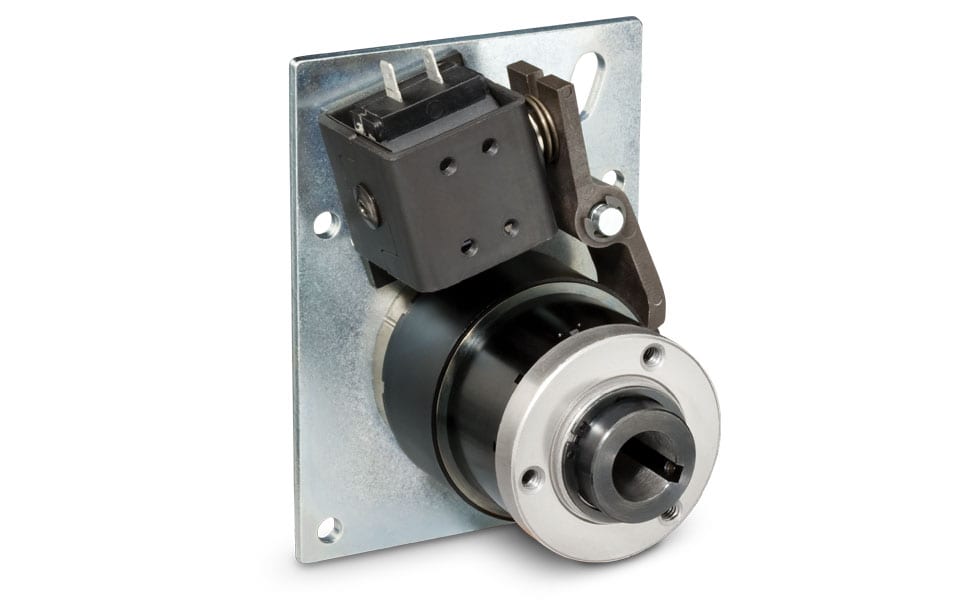

CB Clutch Brake

Clutch Engineering offers the Warner Electric CB series clutch/brake for use in applications such as indexing rotary tables, printing heads, cut-off knife systems, and other mechanical systems. Start and stop positioning can be maintained within +1/2° at speeds up to 1800 rpm, and the CB clutch brake is completely self-contained. Standard models are available for 12, 24, or 90 VDC or 115 VAC operation. This electrically actuated clutch/brake package is designed for systems that require a continuous rotational input that is converted into starting and stopping a load. This clutch brake product can be operated with the use of an AC or DC power source.

Torque range: 25 to 5,000 lb-in (2.8 to 565 Nm)

Typical applications: Indexing rotary tables, printing heads, cut-off knives

EM Clutch Brake

Clutch Engineering offers Warner Electric electro modules (EM) that can be assembled together and mounted in a variety of industrial mechanical systems. These products can be assembled to form a clutch, brake, or clutch/brake combination. They can be mounted directly onto a NEMA C-face motor or reducer, or can they be base mounted to meet the needs of a mechanical system. These clutches and brake products are also maintenance-free and can function without needing needing any intermittent lubrication. This simplifies your processes and reduces your overall maintenance costs. When there is a speed difference between the drive and the driven axis, only the use of single or multidisc clutches or brakes is permitted. With zero speed difference or engagement at standstill, the use of a tooth clutch or brake becomes possible.

Torque range: 16 to 95 lb-ft (21 to 128 Nm)

Typical applications: Material handling, robotics, mobile equipment