Clutch Engineering provides PT Tech products and specializes in the distribution of industrial power transmission products. As a part of our diverse product lineup, we are proud to feature brakes and torque limiters from PT Tech. Our knowledgeable staff can offer insight and technical support for complex needs, while we can also make product recommendations to ensure compatibility with your systems. Since 1978 PT Tech has served customers in the mining, tunnel boring, steel manufacturing, aggregate, road-working, and recycling markets. Today, their growing line of reliable products, which includes brakes (HCDB and CDB), clutches, and torque limiters (SL and SLQ), can be found in industrial equipment around the world. PT Tech began by developing the first TLC Torque Limiter for cutterheads used in underground mining machines. Now they provide the mining industry’s standard for protecting drive systems.

Whether you are maintaining or upgrading existing equipment for use in crane applications, mining operations, steel mills, or other environments. These specialized solutions will help to optimize your mechanical processes and operations.

Reliable construction of components takes a great deal of expertise and experience. These products are targeted for many common and critical applications, so you can be certain that you an edge when choosing, installing, and taking advantage of these high-quality products. Our team of applications engineers will be able to support your decision making process to ensure you are choosing the best parts for your application. Caliper disc brakes from PT Tech are a simple replacement for existing drum brakes in overhead cranes, while torque limiters can be found in a wide variety of industries like mining, steel, and wind energy. Clutch Engineering seeks to provide the best solutions for even the most demanding of applications.

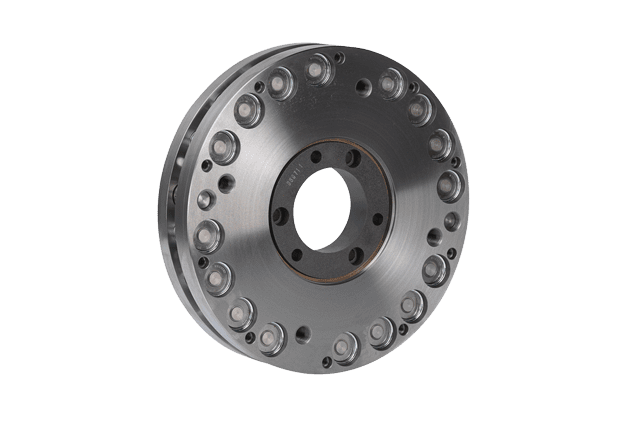

SLQ Torque Limiter

Clutch Engineering offers SLQ series friction-type torque limiters. These well-made products do not require any adjustment at installation or throughout their full wearlife. This is a friction-type torque limiter, which offers great benefits for industrial applications such as mining operations and advanced material handling. They do not require lubrication and resetting after a slip has occurred is not necessary for continued use. Wear can also be measured without disturbing the unit, giving you accurate and readily available information about the status of your equipment. While slipping, this well-made torque limiter will continue to transmit torque to align with the unit’s torque setting.

Torque range: 438 to 3,828 lb-ft (594 to 5,190 Nm)

Typical applications: Mining, steel, material handling

SL Torque Limiter

PT Tech’s SL series torque limiter is available from Clutch Engineering. These torque limiter products are specially designed and manufactured to be integrated into mining applications. Each SL torque limiter as capable of protecting critical mining applications when torque reaches dangerous levels in critical equipment. While slipping, this torque limiter is still able to transmit torque equal to the unit’s torque setting, which results in safer and more predictable operations. Additionally, since this is a friction-type torque limiter, it is not necessary to reset the torque limiter after a slip occurs. This saves you time and expenses by avoiding costly equipment repairs. The SL series torque limiter is designed to operate at motor speed. In most drive systems the prime mover represents approximately 90-95% of the equivalent inertia.

Torque range: 3,312 to 4,584 lb-ft (4,490 to 6,215 Nm)

Typical applications: Mining equipment