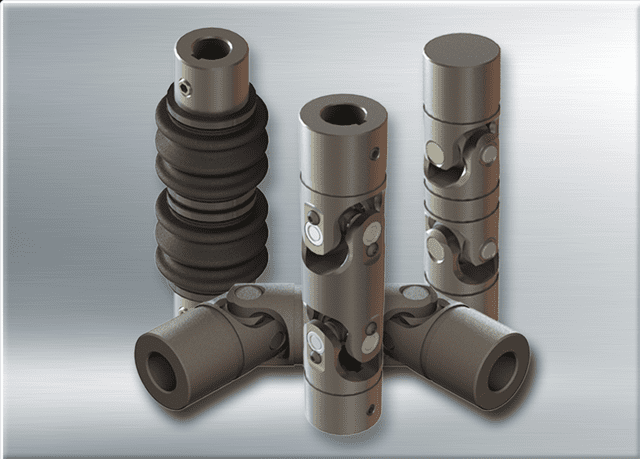

Double Universal Joint

Belden Universal’s double universal joints are made to the same exacting standards as their single universal joints. Double universal joints allow for a larger operating angle, and using phased double joints allows for equal input and output speeds, provided operating angles are equal. Torque range: 18 to 5,735 lb-in (2.1 to 648 Nm) Typical applications: Metalworking machinery, printing machinery, conveyors, packaging systems, steering systems, machine tools

Geared Mill Spindles

Renold Ajax geared mill spindles offer high power density and long life. Renold uses a roll end piloting system to reduce bore wear and vibration. Typical applications: Roughing mills, finishing mills

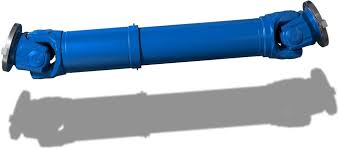

Gewes Cardan Driveshafts

Gewes cardan shafts are high quality, low maintenance, and reliable. They transmit torque while allowing for misalignment between driving and driven shafts. With a variety of sizes, lengths, angles, slips, and flanges available, Gewes cardan driveshafts can meet the specific needs of nearly any application. Torque range: 73 to 165,951 lb-ft (100 to 225,000 Nm) Typical applications: Steel mill machinery, paper mill machinery, pumps, amusement rides, marine propulsion, wastewater treatment