CH Series Clutches and Brakes

Clutch Engineering offers Logan CH clutches and brakes, with options for convenient self-lubrication. These products can be air or hydraulically actuated and can be used for either wet or dry operation. Type CH clutches are also approved by the American Bureau of Shipping (ABS). When using these parts, pressurizing the actuating cylinder causes the clutch’s discs to clamp. Torque is then transferred from the disc pack to the splined drive ring. These products can feature self-lubricating seals that help to reduce downtime and decrease costs. The cylinder housing for these products also feature enhanced corrosion resistance. Torque range: 49,000 to 1,280,000 lb-in (5,532 to 144,000 Nm) Typical applications: Marine propulsion, mooring winches, mine hoisting equipment, mining conveyors

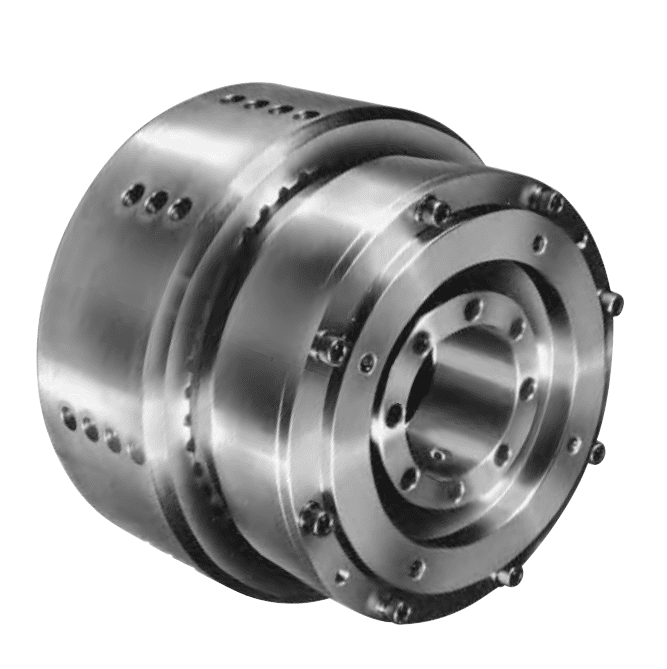

HC Clutch

The compact size of the HC Clutch makes these units perfect for incorporation within a gear housing. Clutch Engineering offers these Wichita HC clutches, which are oil-immersed clutches designed for end-shaft or through shaft mounting configuration. All torque transmitting members are designed to perform for continuous heavy duty industrial operation. All units incorporate provisions for forced oil cooling allowing high energy engagements to be made without causing thermal distress within the disc pack. Cooling oil is introduced into the clutch from an external supply. This oil enters the unit through axial holes located in the shaft. Torque range – 8,511 to 191,028 lb-ft (11,540 to 259,000 Nm) Typical applications – Marine Gears, Winch Drives and Conveyors

Meslu Clutches

Available from Clutch Engineering, these American Vulkan Meslu clutches can be used for dredge pumps, marine drives, auxiliary drives, and other mechanical systems. These well-designed clutches are dry-running, pneumatically actuated, and feature a double-cone construction. In these products, friction lining wear is automatically compensated for, better providing you with an ideal clutch solution. They also operate free of backlash and do not produce any axial load. The electrical part comprises the Monitoring Device. This device is able to detect clutch slippage and monitor the twist angle of the highly flexible coupling in order to protect the drive train. Torque range: 5,900 to 232,332 lb-ft (8 to 315 kNm) Typical applications: Dredge pumps, marine drives, auxiliary drives

VC Clutches and Brakes

Available form Clutch Engineering, the Eaton Airflex VC element assembly is often used for grinding mills, marine propulsion systems, and metal forming machinery. This high-quality clutch and brake product is an air-actuated constricting drum unit. The VC's ventilated design and construction allows for the rapid dissipation of heat that can be generated during operation. The torque that the unit experiences is carried by torque bars, and leaf springs function to retract the friction shoes when air pressure is released. Due to this construction, all components are conveniently available as replacement parts when refurbishing the unit. The type VC element assembly is specifically constructed for severe clutch or brake applications. These include applications in which large inertia loads and sustained slippage would otherwise result in a loss of torque and a reduced operating life. Torque range: 27,000 to 3,660,000 lb-in (3,050 to 413,057 Nm) Typical applications: Grinding mills, marine propulsion, metal forming machinery