CBC Clutch/Brake Combination

Clutch Engineering offers the Eaton CBC, for use with various mechanical applications such as punching machines, printing machines, presses, and other industrial equipment. This clutch/brake combination features a compact design that can effectively apply braking pressure to moving equipment within for your critical operations. This particular product combines an air actuated disc clutch and a spring applied disc brake. Due to the CBC's simple design, over lapping is not able occur between clutching and braking, giving you a better optimized product solution. This, combined with its high thermal capacity and low air consumption, makes this clutch/brake product ideal for a great variety of high speed, high cyclic, and heavy-duty industrial applications. Dynamic brake torque range: 10,900 to 135,000 lb-in (1,231 to 15,253 Nm) Static clutch torque range: 18,700 to 290,000 lb-in (2,113 to 32,765 Nm) Typical applications: Punching machines, printing machines, shears, stamping and forming presses

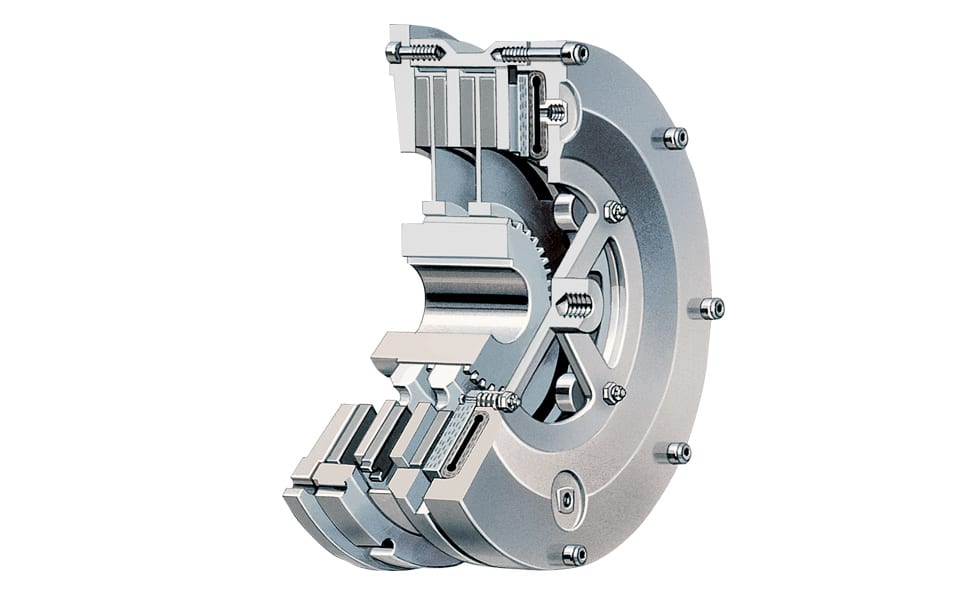

CCB – Clutch/Brake Combination

Clutch Engineering offers Wichita Clutch/Brake Combination (CCB) units, for use with applications such as stamping presses, can making equipment, metal forming equipment, and other industrial machinery. These high-quality CCB units are compact assemblies that combine a high-performance clutch and spring set brake to provide fast and smooth cycling for various industrial needs. An air tube is used to actuate both the single plate clutch and the single plate brake. The Wichita Combination Clutch-Brake can reliably function for the cycling needs of your equipment in a range of applications. The simple Wichita air tube concept combines an air actuated clutch and a spring-set brake in a compact disc design. Torque range –23,000 to 540,600 lb-in (Clutch), 4,500 to 258,400 lb-in (Brake) Typical applications – Stamping Presses, Can Making Equipment

Low Inertia Clutches and Brakes

Clutch Engineering offers Wichita Low Inertia clutches and brakes, for applications that include presses, shears, and other industrial equipment. These clutch and brake parts are air applied, spring released disc style units that give you more control over your braking pressure. When in use, these products develop torque proportional to the air pressure applied. The units are also designed to be free from effects of centrifugal force and self-energization. Low inertia start/stop parts reduce the acceleration times of each unit, which allows you to benefit from more cycles per minute, as well as a reduction in heat generation. Wichita Clutches engage smoothly and quietly, without shock or impact. They are also able to utilize their spring release construction to release completely in a fraction of a second. Extremely fast action is also possible because of the small volume of air required for these high-quality clutches and brakes. Torque range – 3,160 to 17,850,000 lb-in (340 to 1,204,000 Nm) Typical applications – Presses, Shears, Bulk Material Handling and General Industrial Equipment

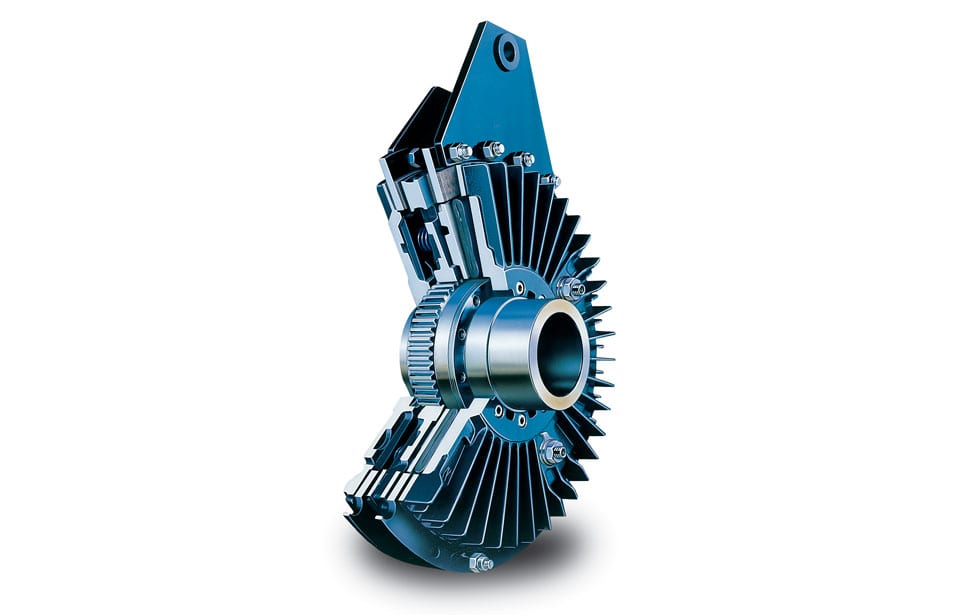

Lutex LKB Clutch/Brake

Available from Clutch Engineering, the Desch Lutex LKB combination clutch/brake (C-B-C) is compatible with many systems that require braking functionality, including industrial presses and shears. This brake is spring applied, and when sufficient air pressure is applied, the brake disengages, engaging the clutch. The LKB series is able to cover most standard clutch/brake mounting arrangements. This clutch/brake has a low moment of inertia and a compact design for integration into machinery that can have tight space limitations. The brake disc is mounted on the press/machine frame whilst the clutch disc is mounting on the flywheel. The piston is mounted on the hub and is free to move axially between the hub and the cylinder. Contact our team at Clutch Engineering with any product or purchasing questions. Clutch torque: 184 to 84,820 lb-ft (250 to 115,000 Nm) Brake torque: 103 to 47,941 lb-ft (140 to 65,000 Nm) Typical applications: Presses, shears

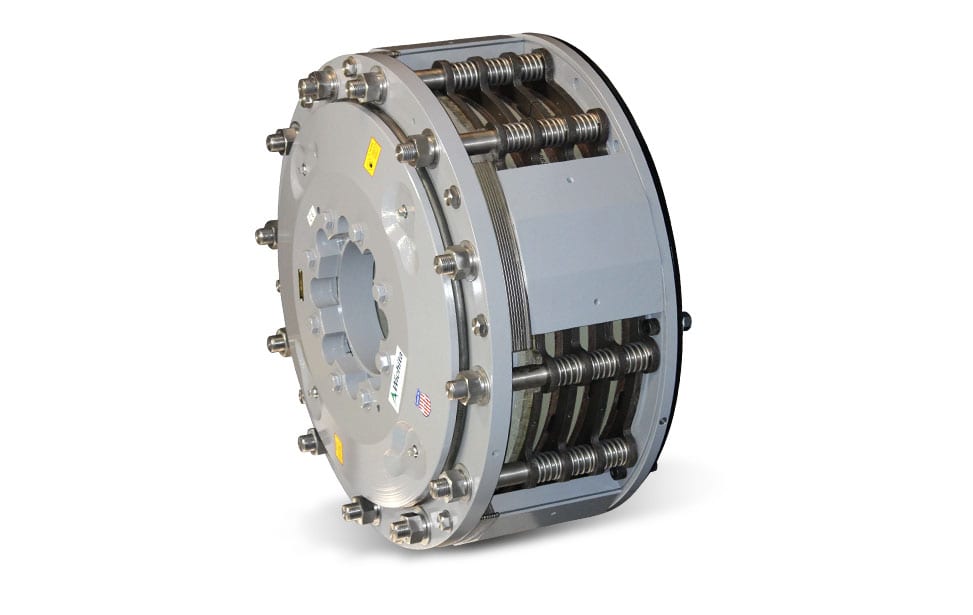

Spring Set Brakes

Clutch Engineering offers Wichita Clutch Spring Set Brakes (SSB) that are used for enhanced safety in industrial environments and for the protection of various mechanical systems. Wichita Spring-Set Air Release Brakes are ideal for fail-safe protection of process equipment. These spring set brakes are similar to the available Low Inertia units, and they are also specially designed to avoid the effects of centrifugal force and self-energization that other products can face. Using low inertia start/stop parts reduces acceleration times, which leads to more cycles per minute and also reduces generated heat. Constructed of high strength cast iron, this improved design has thick friction discs for longer wear life. The fast acting airtube design also assures quick, smooth stops. Torque range – 451 to 5,355,000 lb-in (51 to 605,016 Nm) Typical applications – Presses, Shears, Bulk Material Handling and General Industrial Equipment