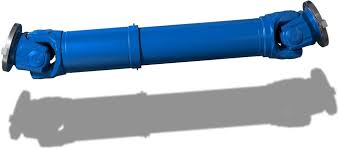

Gewes Cardan Driveshafts

Gewes cardan shafts are high quality, low maintenance, and reliable. They transmit torque while allowing for misalignment between driving and driven shafts. With a variety of sizes, lengths, angles, slips, and flanges available, Gewes cardan driveshafts can meet the specific needs of nearly any application. Torque range: 73 to 165,951 lb-ft (100 to 225,000 Nm) Typical applications: Steel mill machinery, paper mill machinery, pumps, amusement rides, marine propulsion, wastewater treatment

UF Joints (Fixed)

GKN Lobro RF constant velocity joints allow shaft angles up to 40° and are fixed, providing no axial movement. Length compensation is possible through use of a splined shaft joining the fixed joints. RF fixed joints provide constant angular velocity, even when the input and output angles aren’t equal. Torque range: 427 to 7,744 lb-ft (580 to 10,500 Nm) Typical applications: Steel mill machinery, paper mill machinery, dynamometers, marine propulsion

VL Joints (Plunging)

GKN Lobro VL constant velocity joints allow shaft angles up to 18°, and can plunge to allow for axial movement. VL plunging joints provide constant angular velocity, even when the input and output angles aren’t equal. Torque range: 427 to 29,502 lb-ft (580 to 40,000 Nm) Typical applications: Steel mill machinery, paper mill machinery, dynamometers, marine propulsion